Forklifts are powerful machines and are often an ideal solution for transporting, lifting and stacking palletised goods. However, what if you can’t justify the cost of a forklift or it isn’t suitable for your workplace?

Forklifts are large, need ample room to move, and have a price tag to match. They also require all operators to undergo qualified forklift training to be allowed to drive them.

In most cases, a far more affordable option is the use of a Pallet Stacker.

These Forklift-like pallet stackers are cost-effective and bring increased efficiency to situations where a forklift isn’t practical.

Do I need a forklift licence to operate a pallet stacker?

See this link to the Approved Code of Practice for Forklifts on WorkSafe's website for more information.

Pallet Stackers Overview

Lifting and stacking loads by hand, either heavy or light, is laborious. These time-consuming tasks can become a potential hazard which can place your workers at serious risk of back strain and injury and reduce productivity.

Pallet Stackers are ideal for reducing these hazards, particularly in warehouses where the reach, size or power of a forklift isn’t needed or isn’t practical.

These machines are designed to be agile and versatile - built for lifting up to 1500kg to heights of up to 5000mm. Not all pallet stackers are created equal. Depending on what you need to lift, some models will be more effective and efficient than others.

We are going to look at:

- The power options are available.

- The different leg configurations and their uses.

- Advanced Features.

1. Power to Lift and Drive

Manually Powered

Manual pallet stackers are entry-level machines. They require the use of a hand pump to lift the forks, and physical force to push the unit around.

Electrically Powered

For situations that require shifting heavier loads safely, efficiently and speedily, then the powered pallet stackers are the way to go.

These units are similar to an electric forklift but provide businesses with an affordable, reliable and economical alternative to its larger counterpart. What’s more, with their simple-to-use control systems, workers can be trained to use them in far less time.

2. Regular, Straddle or Reach Legs

Pallet stackers typically come in one of three leg configurations, each for different scenarios and needs.

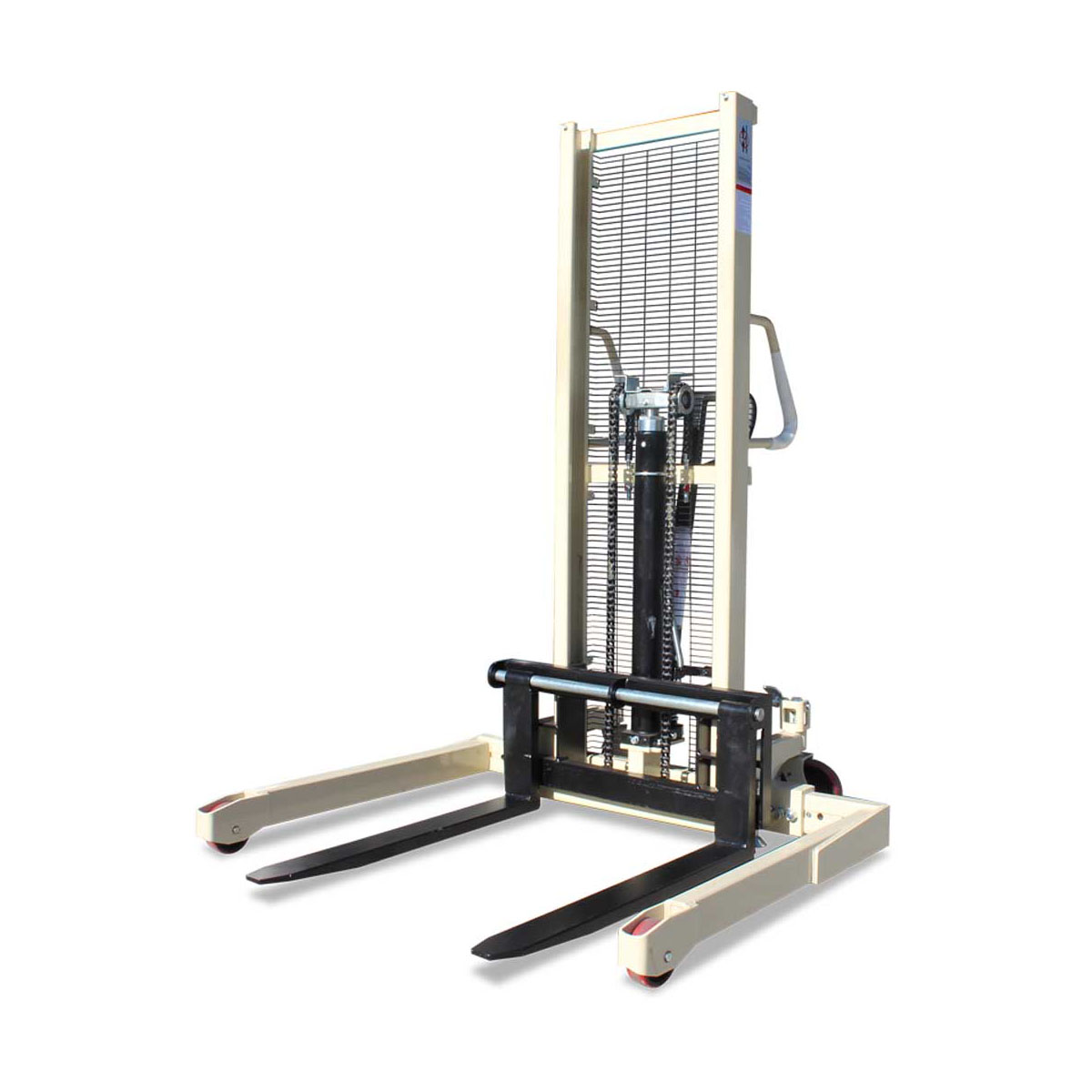

Regular Leg Pallet Stackers

A standard pallet stacker has forks that sit directly on top of its legs. These are typically suitable for lifting most pallets from the two sides that don’t have bottom deck boards.

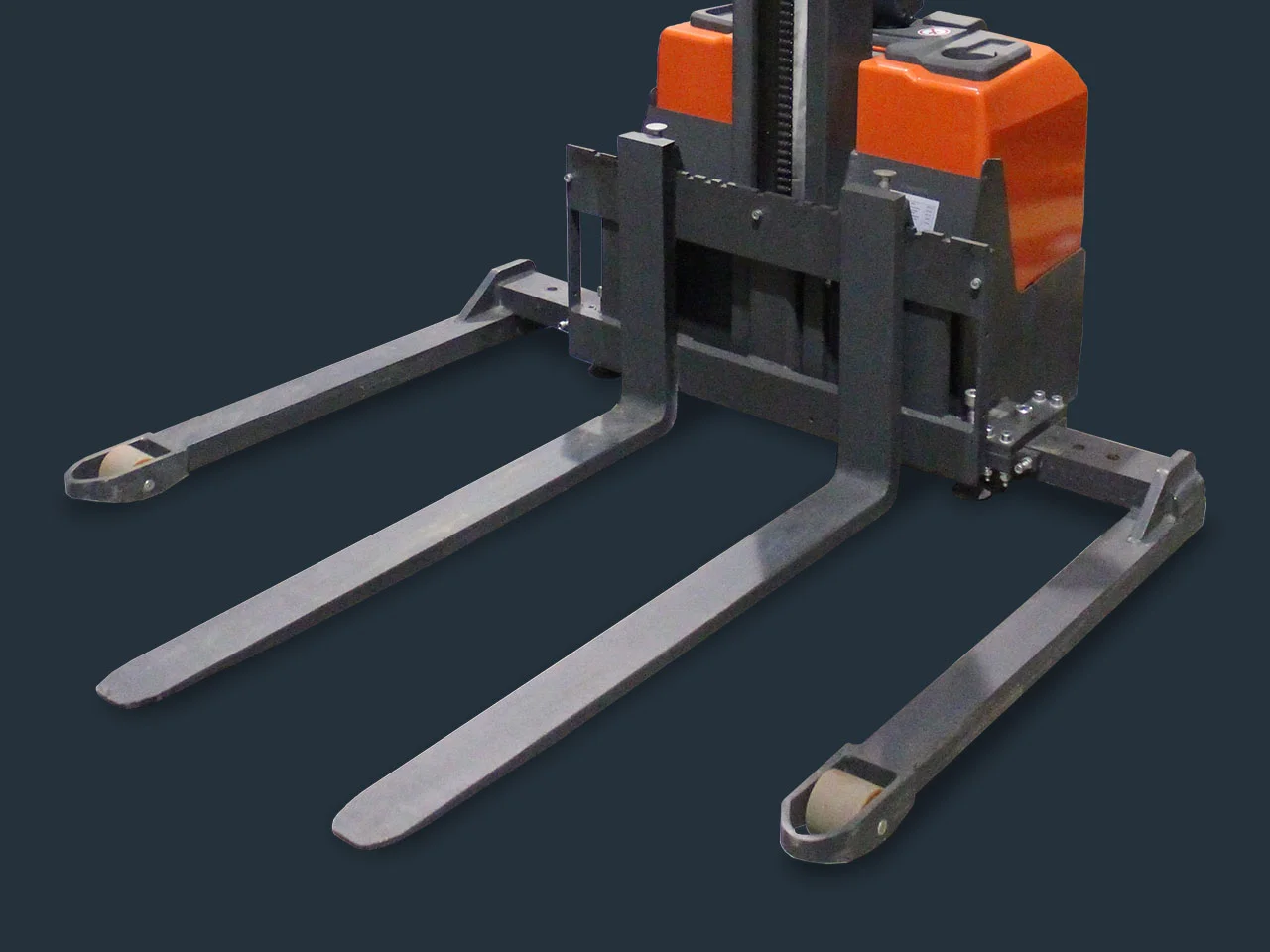

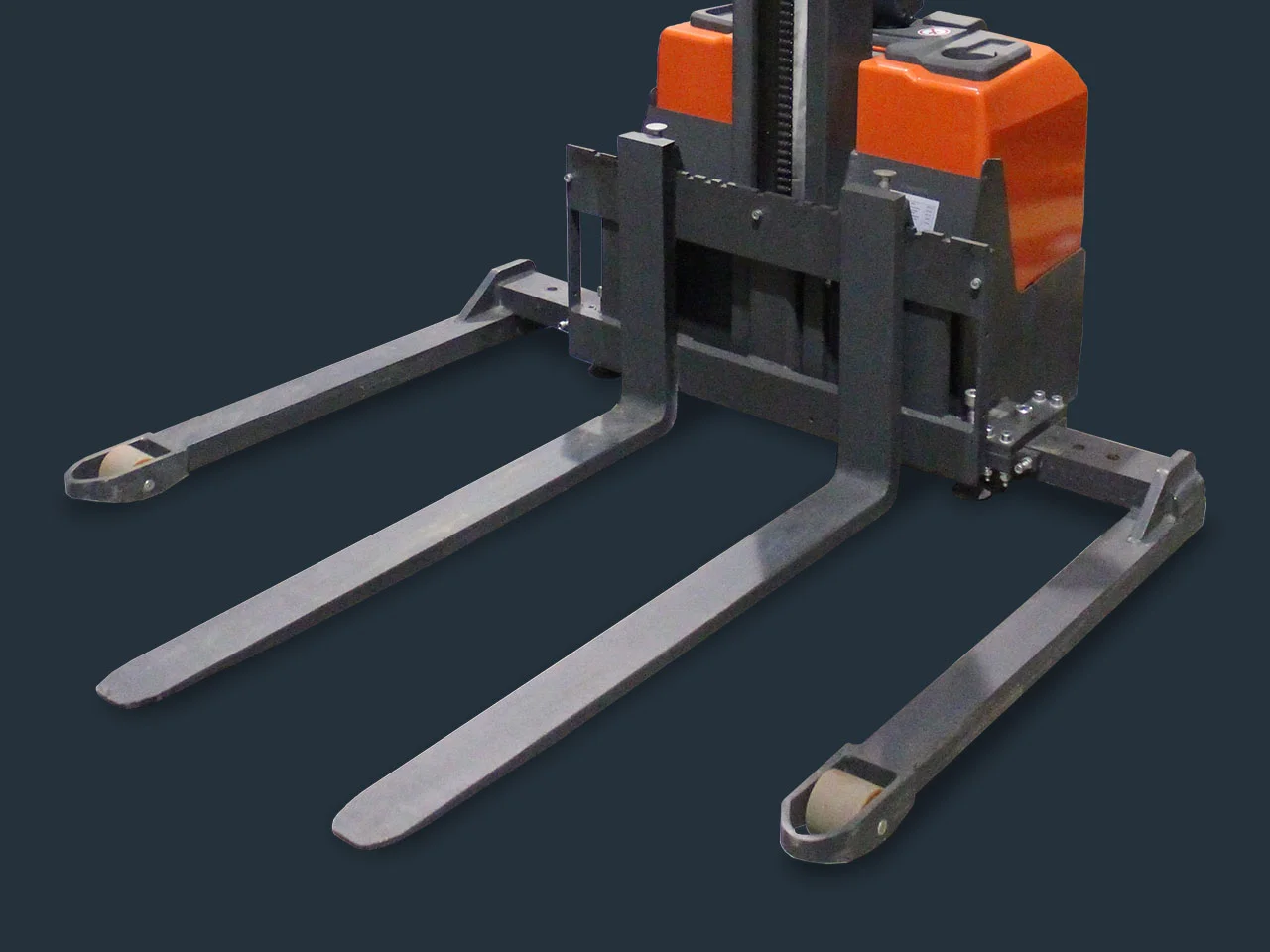

Straddle Leg Pallet Stackers

Depending on the model, straddle pallet stackers have either fixed or width-adjustable legs that sit outside of the forks. This configuration lets the legs sit outside of a pallet while picking it up, allowing the forks to reach much lower and lift pallets from all four sides, including pallets with bottom boards.

Reach Trucks

These pallet stackers are a step up from straddle stackers and are the most forklift-like in appearance and operation. Instead of having legs that fit around the outside of a pallet, reach trucks have forks that extend forward beyond the front of the legs. These are also capable of lifting pallets without bottom boards.

This ability lets this machine move right up to a row of pallets or racking and “reach out” for a pallet without worrying about legs impacting other pallets or items. Meanwhile, the built-in counterbalance stops the stacker from tipping while a load is on the forks in the extended position.

3. Advanced Features

Beyond the basics of how a pallet stacker is powered or its legs configuration, unique features are also available.

Auto-levelling forks

For loading or unloading a pallet while it’s still sitting on the stackers’ forks, these pallet stackers have a photo-sensor on them that will automatically raise or lower the top of the load to a safe working height.

Stainless Steel Finish

In work environments where hygiene is critically important, painted or powder-coated finishes aren’t always suitable. For these situations, we have a range of stainless steel models that great for those clean-room environments and easy to clean.

The Efficient Alternative

Everything seems to be on pallets these days.

Pallet shelving reaches higher, and the aisles grow narrower as we try and fit as much product into our racking as we can. While the diminishing aisle widths may rule out forklifts, pallet stackers continue to provide the agility, speed and efficiency needed to get your work done just as quickly.

So if a forklift isn’t suitable for your workplace - use a Pallet Stacker.