The Mobile Scissor Lift Trolley comes in a range of lift capacities up to 350kg and also has the option of varying lifts that can be lifted. Having the strong castors or wheels and handy wheeling handle they can start off being wheeled at a low level, then raised with the foot operated hydraulic lift to the desired height for off-loading or loading. Then the lift table can be simply lowered by a trigger release built into the handle.

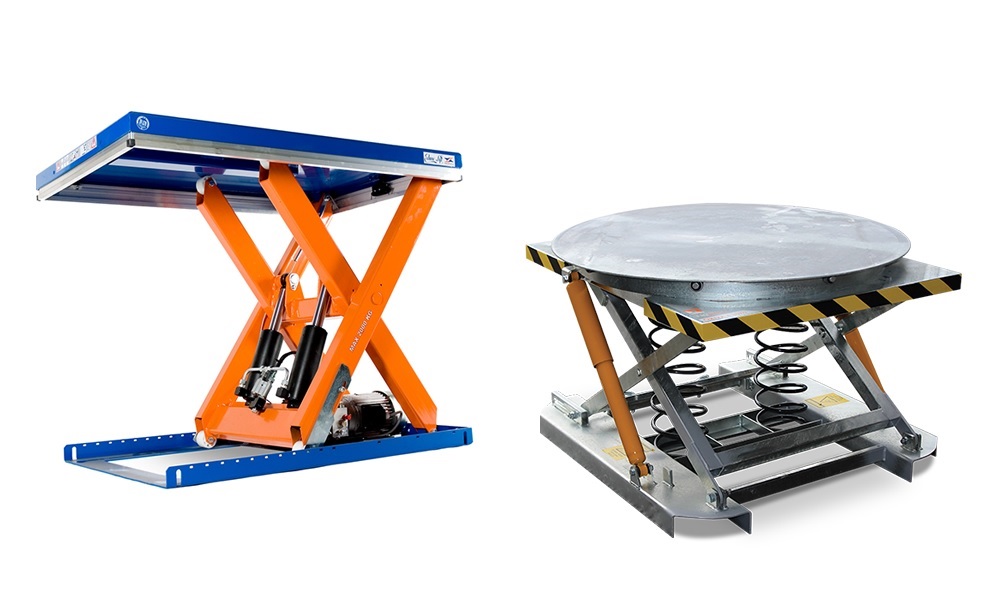

The Stationary Electric Scissor Lift Tables sit on the floor with a solid base plate and have a hydraulic lift to elevate products with the push of a button to reach the ultimate height for unloading or simply using as a work bench at the desired height for comfort and ease of work. With a load and lifting capacity of up to 1000kg these electric scissor lift tables can be positioned in the workplace, or even in the outdoor environment as they are powder coated, so that repetitive lifting and lowering can be done with the push of a button.

A Double Height Electric Scissor Lift Table has a lifting capacity of up to 1500kg depending on the model. Motors or appliances that need repairs or maintenance can be raised to eye level so the maintenance worker is able to carry out their task without having to bend or work at an awkward angle.

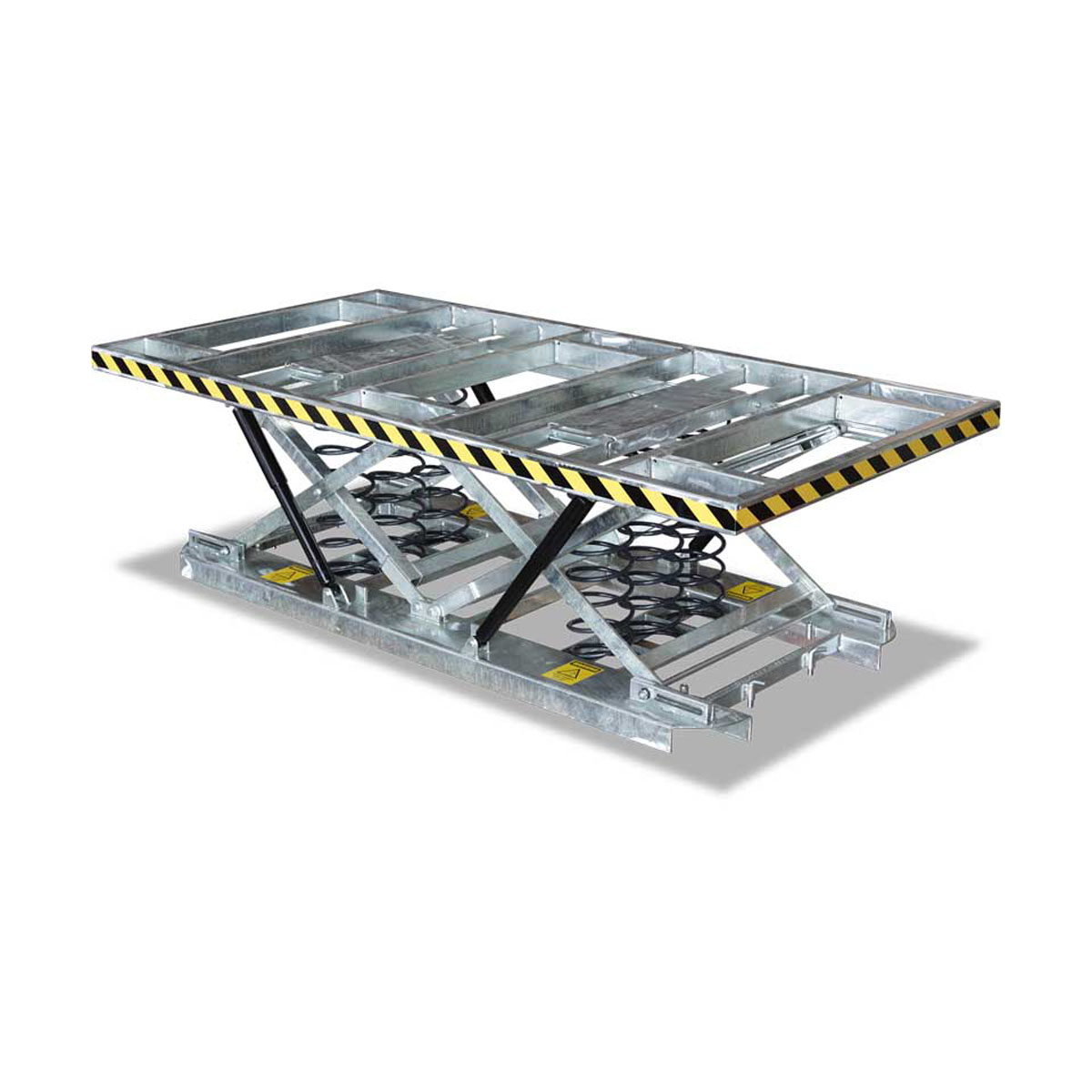

The Galvanised Steel Timber Bearer is spring loaded and has a lifting capacity of up to 1500kg so is ideal for carrying and lifting heavy timber so that wood products can be handled at a safe height without the risk of strain or injury to workers. The springs compress and lower as the weight is applied and as the weight is removed the bearers rise back up again.

Pallet Scissor Lift Tables have a round table top for raising and lowering pallets and a capacity of 2000kg. There is a range available from the non-electric which is suitable for cold, clean and food grade areas, to the Stainless steel spring loaded scissor lifters which again, are compliant with food grade work. Pallets are simply loaded and unloaded ready for the forklift to take the cartons or boxes to their desired location. No bending or lifting required.

Types of Lift Tables

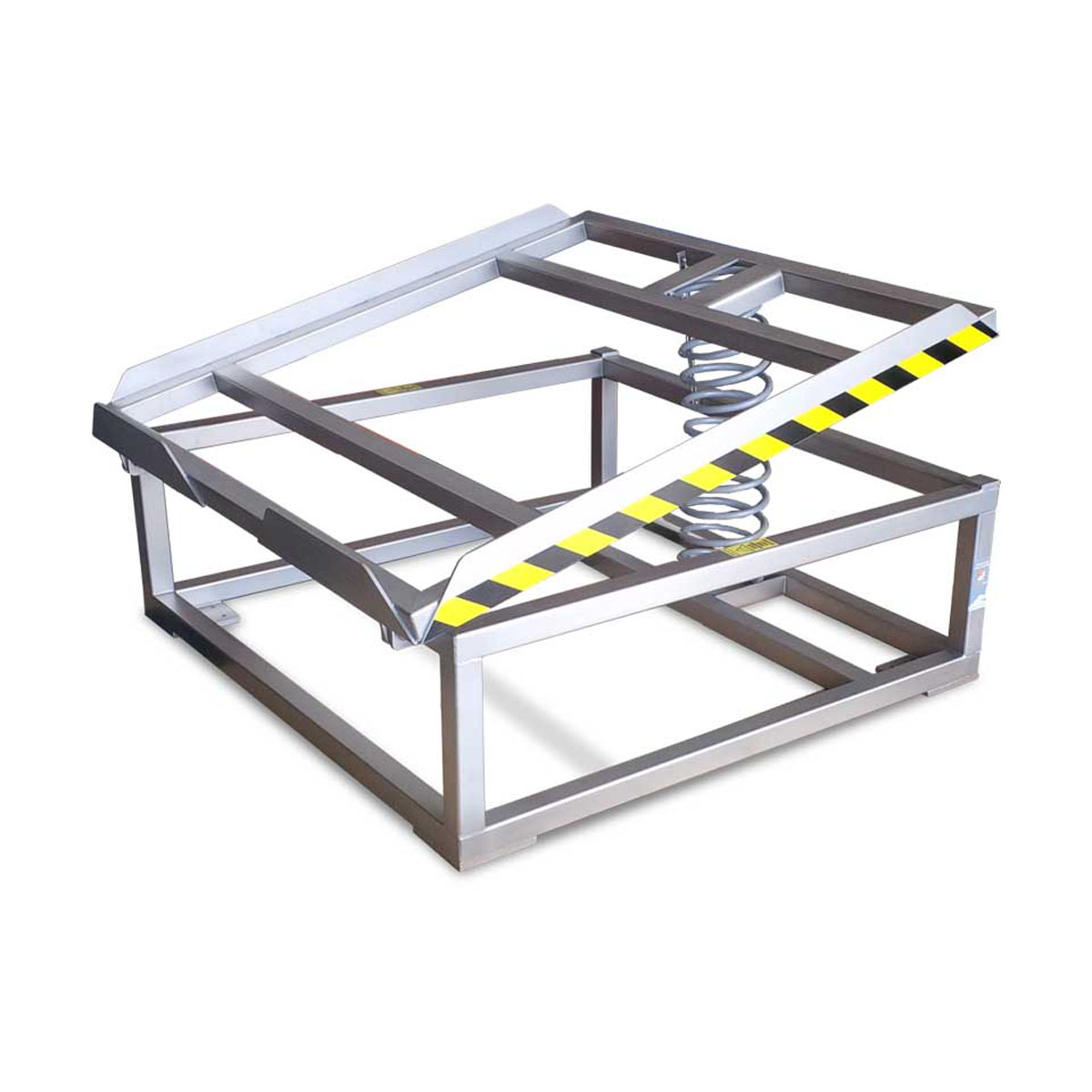

Tilting Lift tables come in a range of styles so the product or bulk storage containers are easy to decant. When the container is full the platform is flat and as the weight is decreased, the spring in the back tips the container slowly up ten degrees. Excellent in hygiene critical areas as well and the open table makes it easier to load cages or cartons full of smaller items that can then be tipped for easy unloading by the service worker.

An overview of Lift Tables

Scissor lift tables are an essential tool in any warehouse or factory situation where boxes, cartons, pallets or other heavy items are needing to be shifted around or worked on at a convenient and safe height. Scissor lift and mobile lift tables are a convenient and essential tool for safe working conditions and operations in vehicle loading and docking ports, pallet loading and unloading, mobility access areas, roll cage handling, furniture upholstering, window cleaning at height, factory work, parts warehouses, mechanical and repair workshops and any industry or factory where the employer is conscious of the need for their workers to operate at a safe level.

Caring for your Lift Table

Maintenance of your lifting table will give the employer a long life of stressless work and lifting. Regular cleaning and oiling of appropriate parts will enhance the life of your lift table, especially in areas where the lift tables are used for hygiene sensitive work. Regular testing of the springs and hydraulics should be carried out by experienced personnel so that the loads are not susceptible to sudden drops or fails because of the lack of maintenance in the lifting apparatus.