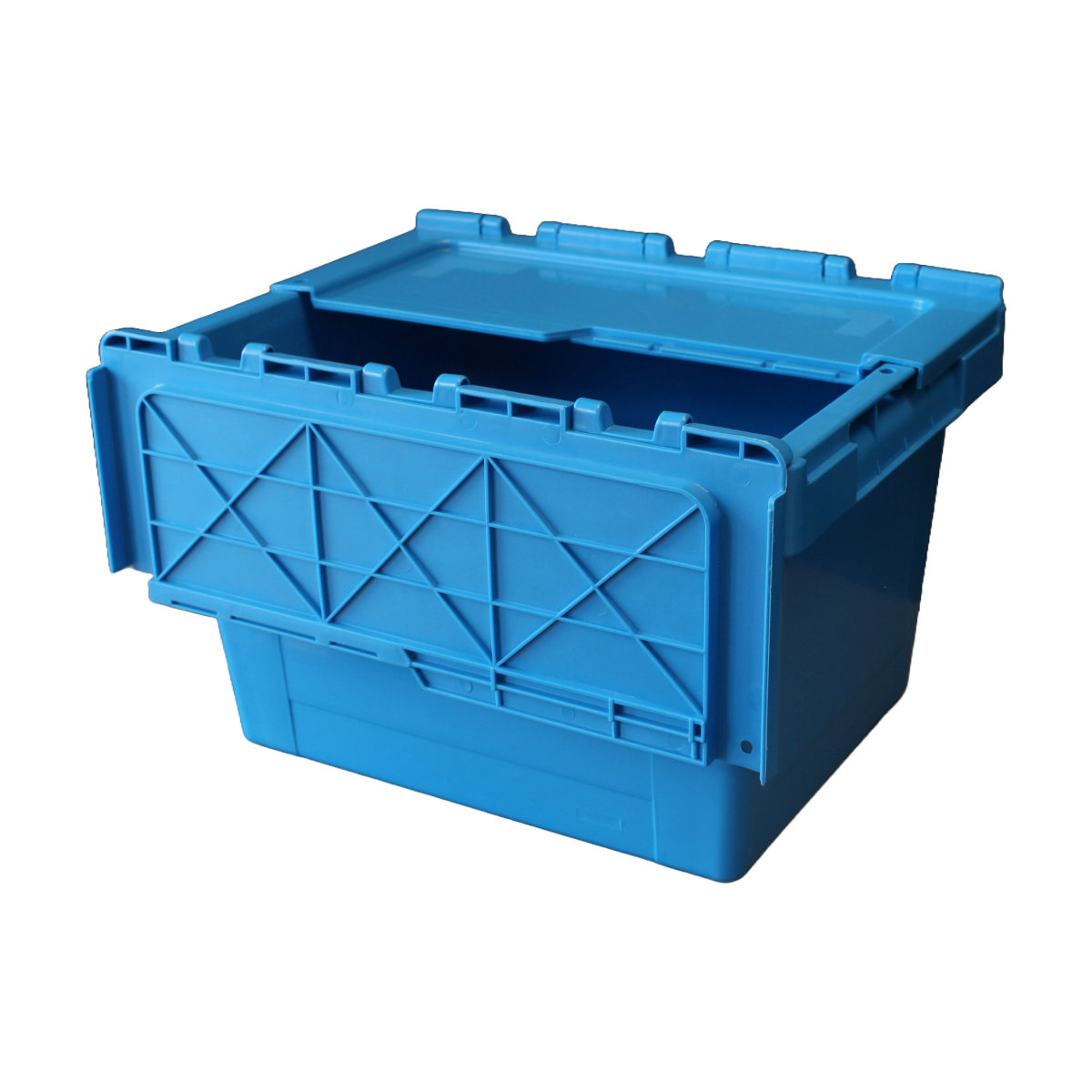

Storage Equipment

Storage equipment is essential for maintaining an organized and efficient warehouse. This category includes pallet racking, shelving systems, mezzanines, and modular drawer systems, among others. By providing optimal storage solutions, these equipment pieces help maximize space utilization, improve inventory management, and maintain a clutter-free work environment.

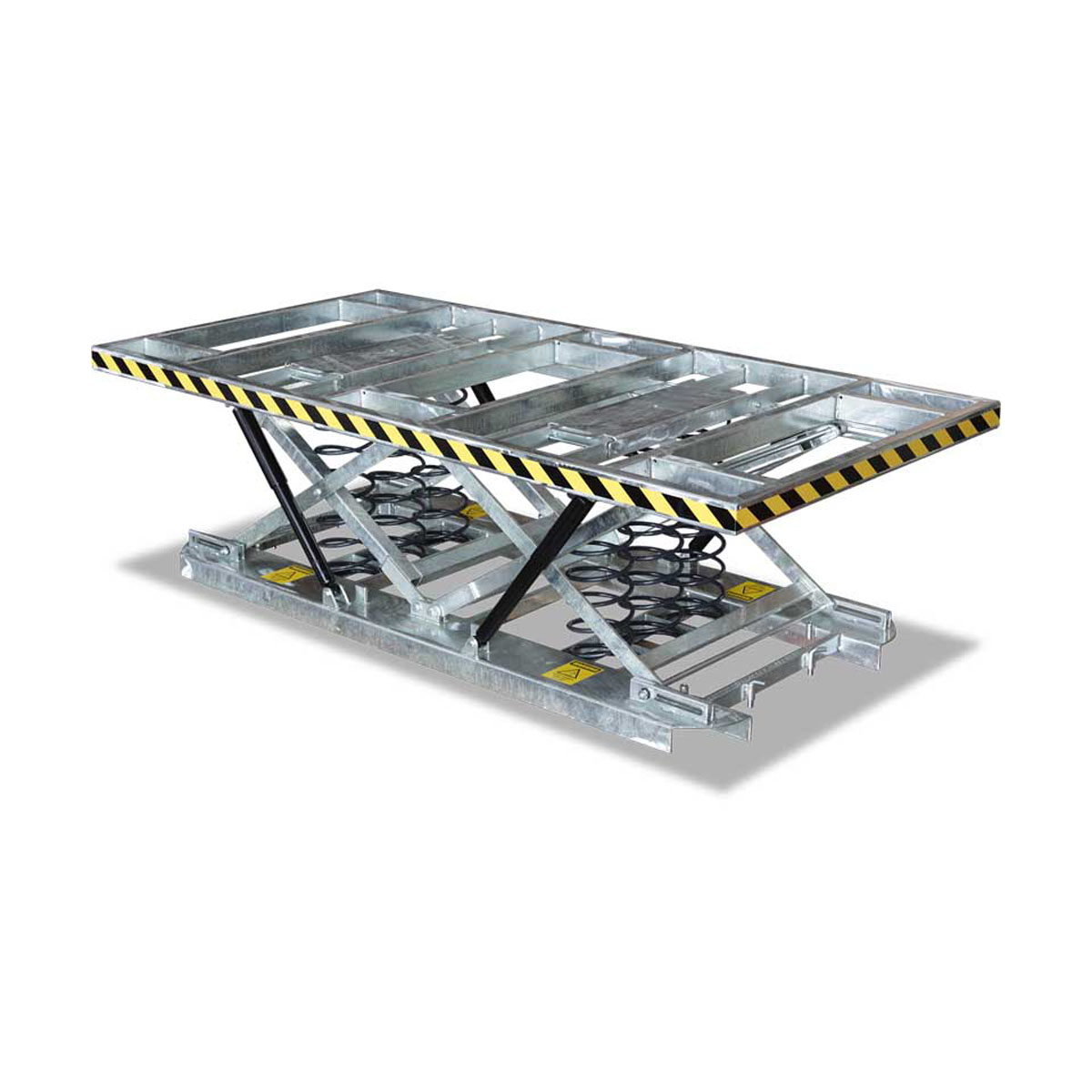

Engineered Systems

Engineered systems are automated solutions designed to streamline and optimize material handling processes. They include conveyor systems, automated storage and retrieval systems (AS/RS), robotic pick-and-place systems, and warehouse management systems (WMS). Engineered systems can significantly increase productivity, reduce labor costs, and minimize human error in material handling tasks.

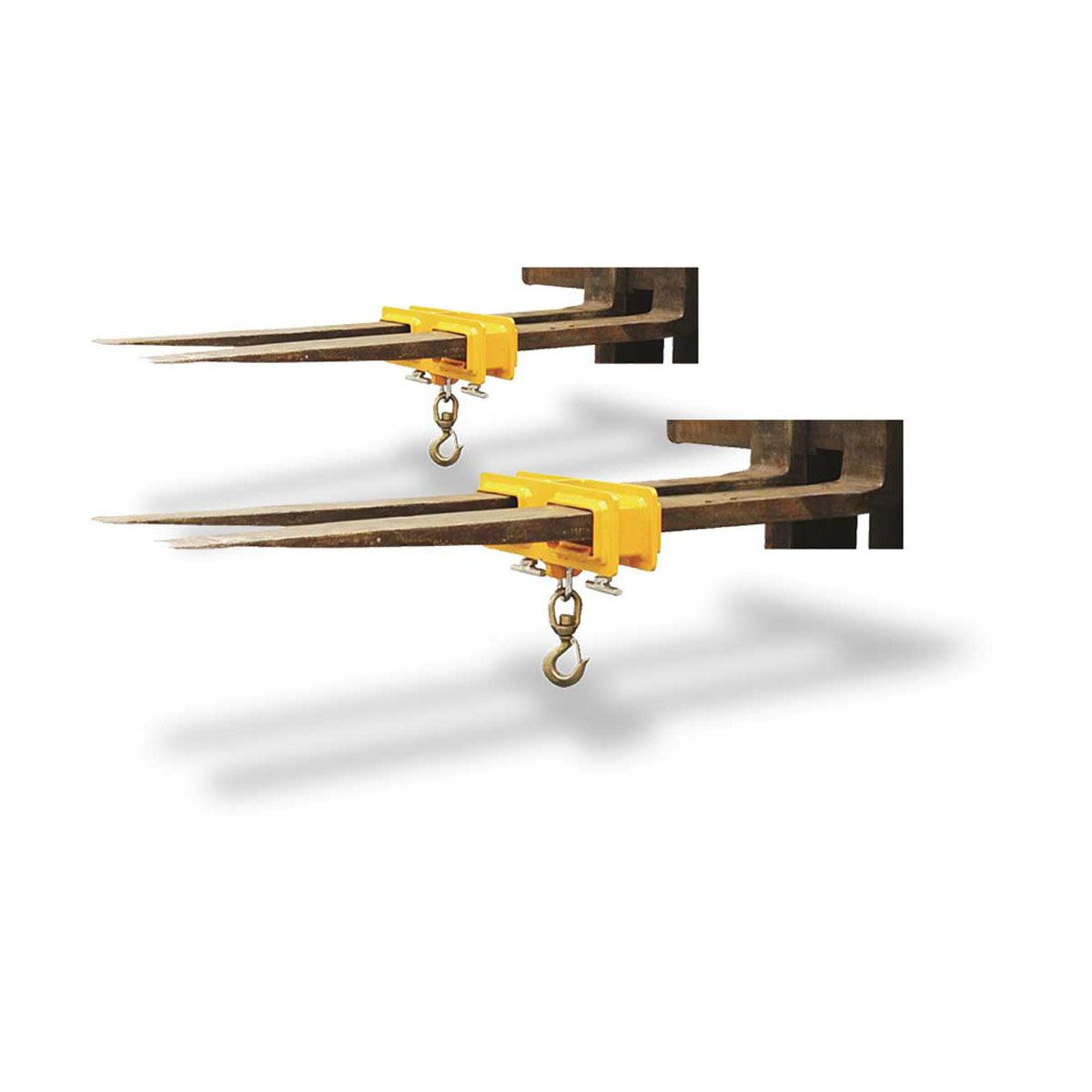

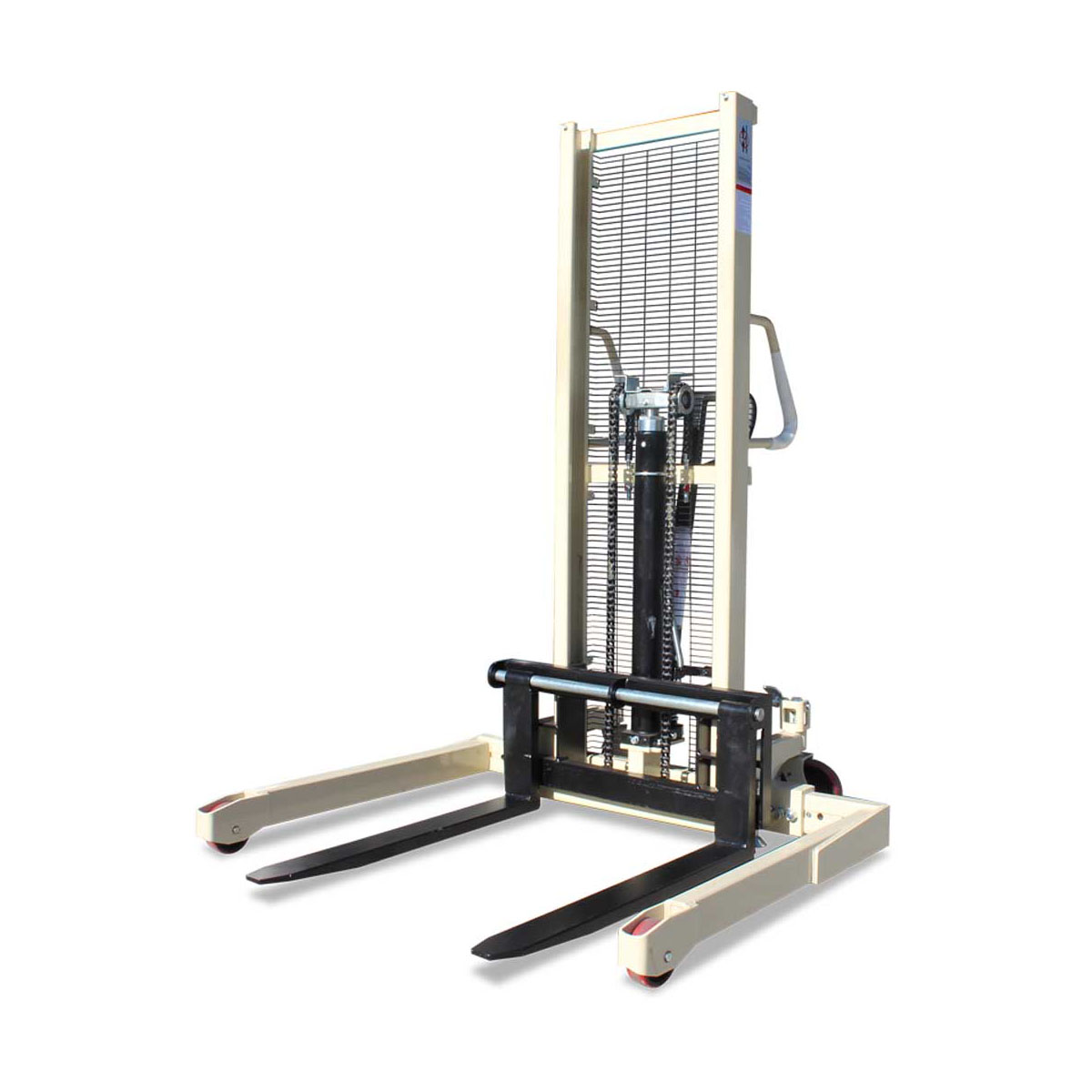

Industrial Trucks

Industrial trucks, such as forklifts, pallet jacks, and tow tractors, play a critical role in the transportation of goods within a warehouse or manufacturing facility. These trucks enable the safe and efficient movement of heavy or bulky items, reducing the physical strain on employees and increasing overall productivity.

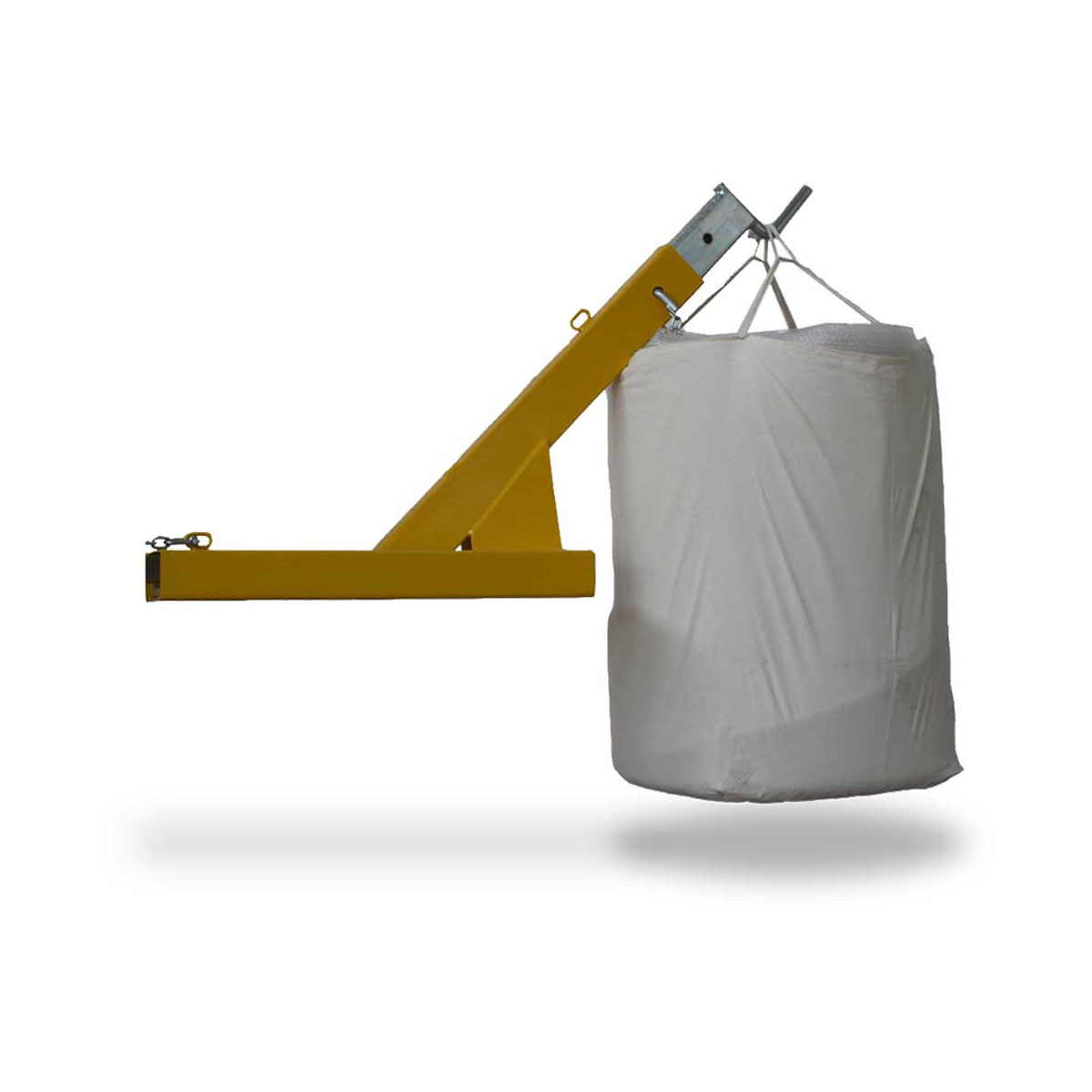

Bulk Material Handling Equipment

Bulk material handling equipment is designed for the transportation, storage, and control of loose materials, such as grains, coal, or sand. This category includes equipment like belt conveyors, bucket elevators, and silos, which are essential for industries dealing with large volumes of bulk materials.

Industry-Specific Solutions

Certain industries, such as food processing, pharmaceuticals, and automotive manufacturing, have unique material handling requirements. Specialized equipment, such as hygienic conveyors, cleanroom lifts, and automated guided vehicles (AGVs), cater to these industry-specific needs, ensuring compliance with regulations and maintaining high standards of safety and efficiency.

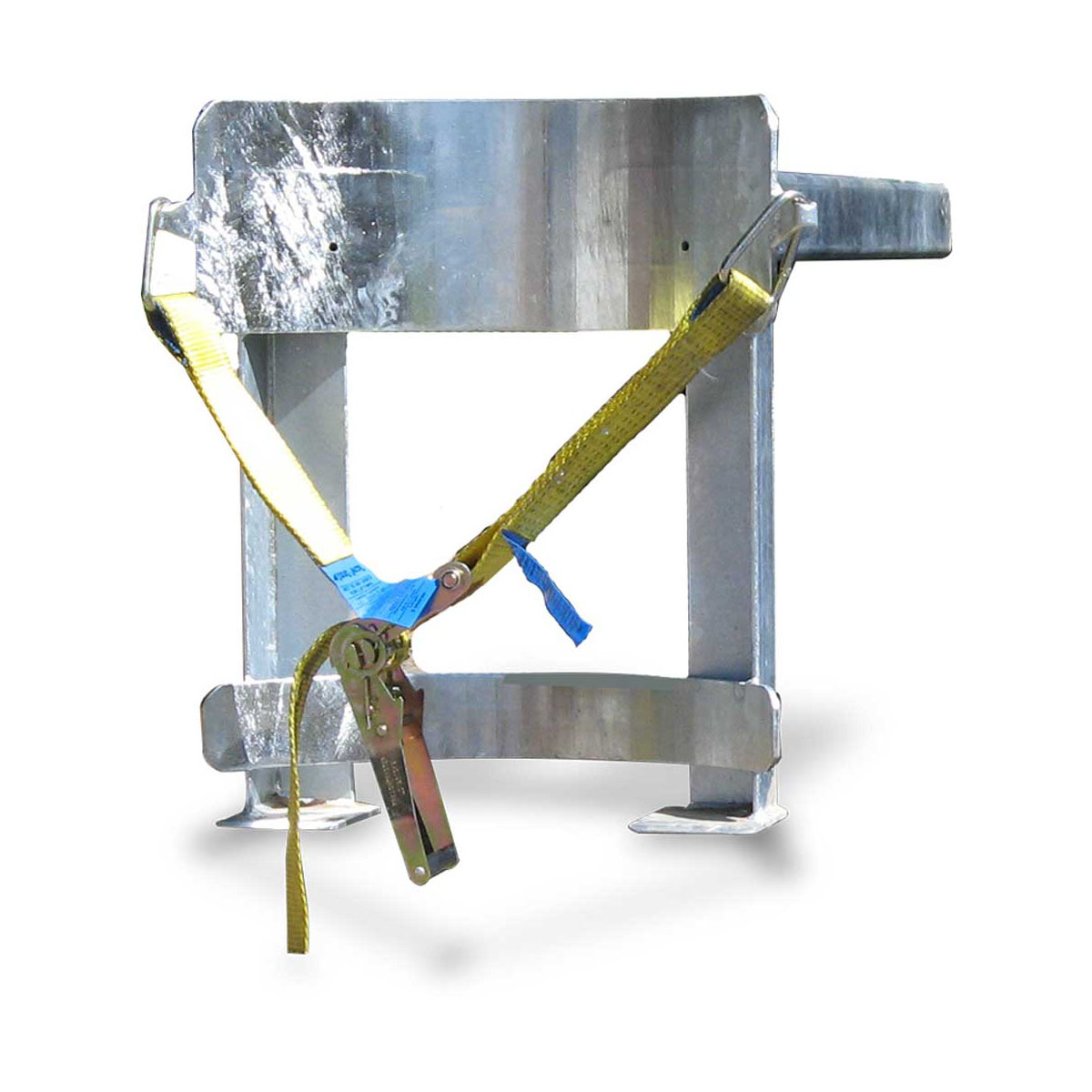

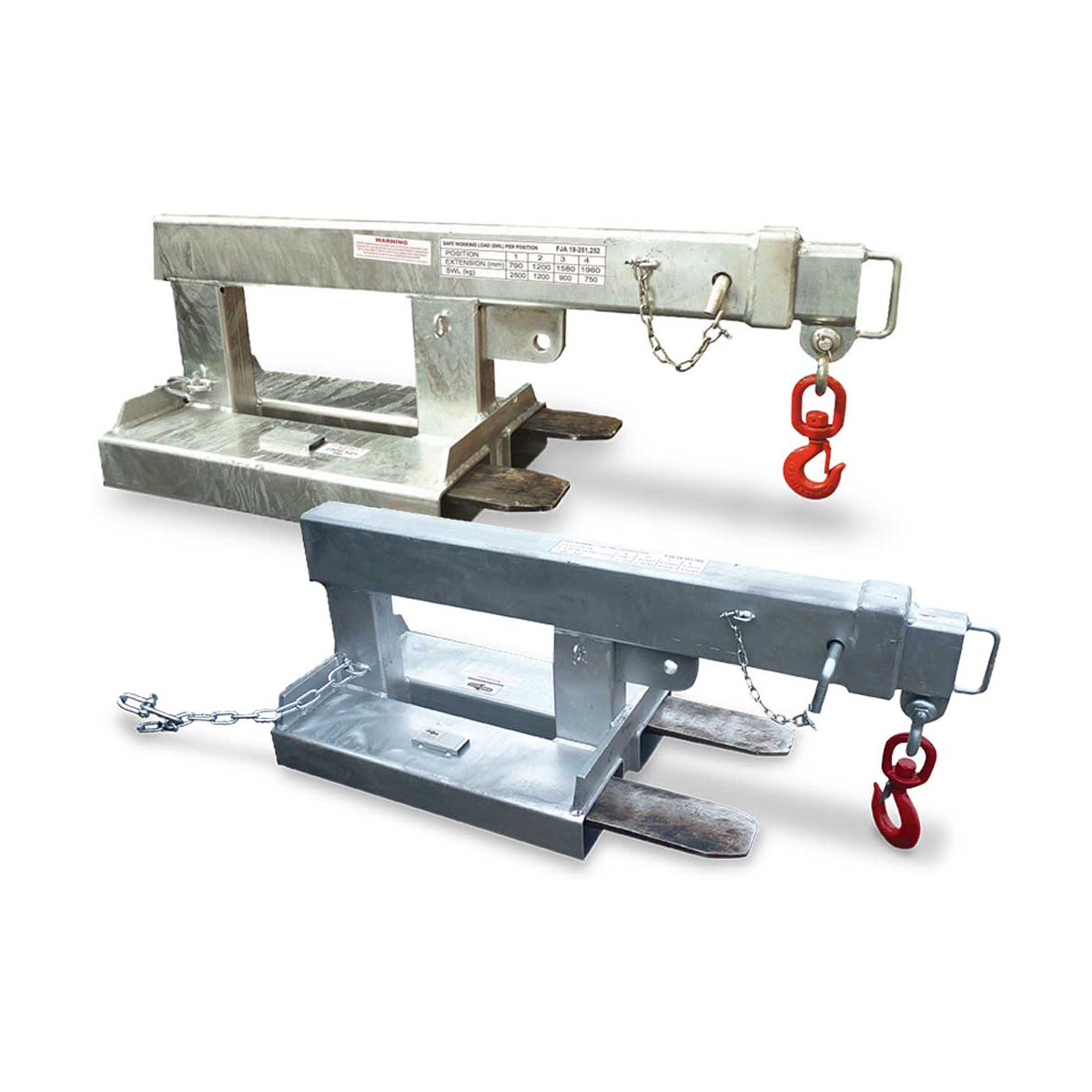

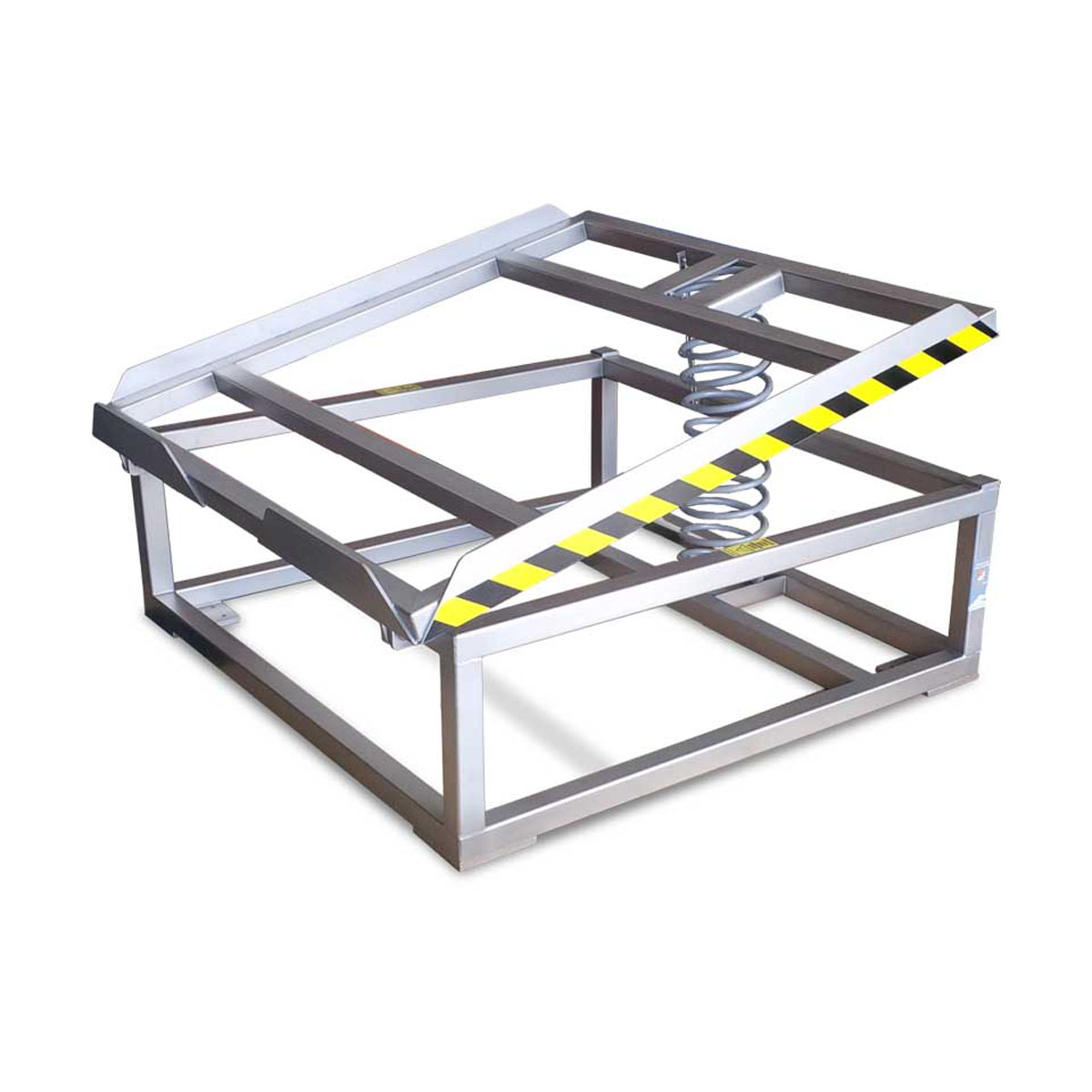

Customizable Material Handling Equipment

Many material handling equipment manufacturers offer customizable solutions to meet the specific needs and challenges of individual facilities. By tailoring equipment to your unique requirements, you can optimize space utilization, increase efficiency, and adapt to changing business demands.

The Astrolift Advantage:

At Astrolift, we are committed to providing our customers with the highest quality material handling equipment and exceptional customer service. Our team of experts works closely with you to understand your unique requirements and recommend the best solutions to enhance your facility's efficiency, safety, and productivity.

Comprehensive Range of Products

Our extensive product range includes storage equipment, engineered systems, industrial trucks, bulk material handling equipment, and industry-specific solutions, ensuring that we can meet the needs of any warehouse or manufacturing facility.

Customizable Solutions

We understand that every business is different, which is why we offer customizable material handling equipment designed to meet your specific challenges and requirements. Our team of experts will work with you to develop tailored solutions that optimize your operations and deliver the best return on investment.

Expertise and Support

With years of experience in the material handling industry, our team of professionals is well-equipped to provide expert advice, guidance, and support throughout the entire process. From initial consultation to after-sales support, we are dedicated to ensuring your satisfaction and the success of your business.

Commitment to Quality and Safety

At Astrolift, quality and safety are our top priorities. We carefully select our products and partners based on their adherence to the highest industry standards, ensuring that you receive reliable, durable, and safe material handling equipment to protect your employees and your investment.

Invest in your facility's success with Astrolift's comprehensive range of material handling equipment, customizable solutions, and expert support. Experience the difference and discover how we can help you achieve your business goals while ensuring a safe, efficient, and productive work environment.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)