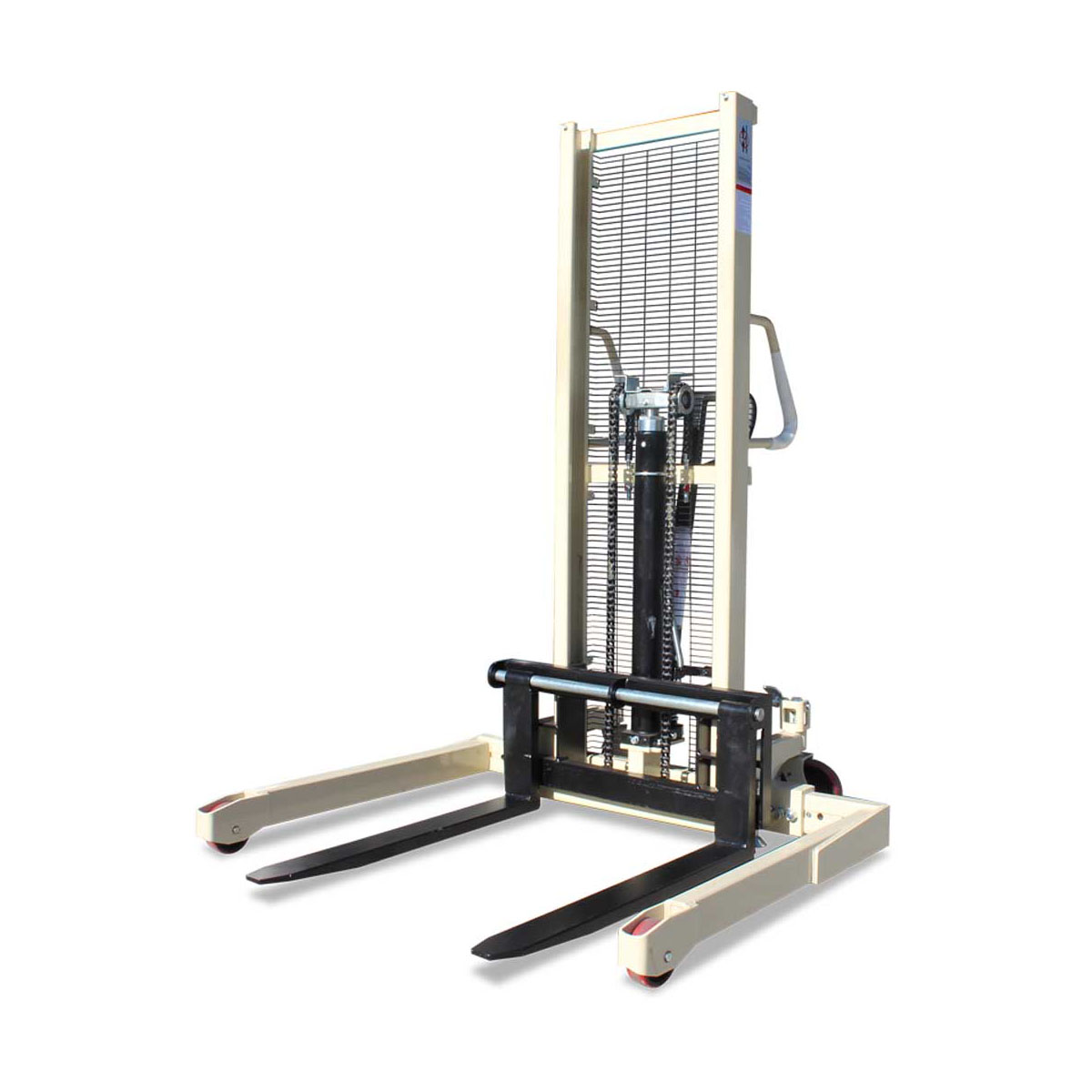

Full Pallet Stacker Product Information

The Electric Counter-balance Stacker is fully electric and able to carry loads of up to 1300kg capacity. The counter-balance built into the back allows the forks to be shifted beyond the front legs so it can be driven right up to the shelving units without coming into contact with the shelf legs or pallets on the ground.

Applications of Pallet Stackers

The industries where pallet stackers are applied include Manufacturing plants, Retail stores, Factory floors, Warehouse facilities etc.

Pallet stackers are particularly used in warehouses that handle high-volume or mid-sized commodities. A stacker's modest physical footprint allows it to be maneuvered into a variety of configurations quickly and intuitively. This greatly expands their functionality and makes them a valuable tool in a wide range of professional situations.

If you want to get the most out of your stacker, be sure it's being used by trained employees who are following all OSHA regulations. Stackers are effective over a wide range of transport distances, making small jobs swift and efficient while also reducing the work required for longer runs. They're especially excellent for operations that require more loading and maneuvering time with larger, more complex vehicles. They're especially effective for operations that demand more loading and maneuvering time with larger, heavier forklifts or non-motorized pallet carts that require human assistance.

Stackers are often used for small to medium-sized goods weighing between 600 and 2000 kilos. This is combined with their ability to move quickly and precisely, allowing for a quick, safe pace and a steady walk, reducing employee effort and utilizing current technology to reduce workplace stress.

Pallet stackers can be a terrific addition to your organization, and quality providers will have a variety of solutions to fit your specific requirements. Big-duty stackers for lifting heavy materials or nimble stackers for volume work, both enable your workers to go beyond what would be physically or safely achievable with traditional equipment.

Electric Straddle Stacking Machines

The Electric Straddle Stacker has a stainless steel finish which makes it ideal for food grade and cold storage operations. There are several models available with lifting capacity up to 1400 kg. A safe and easy to ride straddle stacker with emergency stop buttons on the tiller and body of the machine.

Electric Straddle Stacker with Auto levelling will ensure the load is kept at an ergonomic height so the operator can load and unload a pallet directly on the forks. With the auto senor the load is automatically raised and lowered to keep it at the correct height for the operator, saving back strain and injury.

Semi-Electric Pallet Stackers

The semi-electric pallet stacker has a manual drive and electric lift. Various models have lifting capacity up to 2000kg and this pallet stacker is great for moving pallets without bottom boards. The adjustable forks spread suitably for the varying pallet sizes.

Pallet Stackers Ideal for New Zealand Businesses.

Every business that has a factory or warehouse with high shelving and a quantity of boxes or pallets that need to be unloaded and stored on high shelves, should invest in one of these electric or semi-electric stackers. They are sometimes called walkie stackers and they are a tool designed to ensure your workers and employees are able to distribute goods and handle materials easier. Time saving and cost cutting is an obvious saving to the bottom line of any business or enterprise so warehouses, logistic departments, factories or any facility that has a large quantity of product that needs to be stacked at height will greatly benefit from one of Astrolifts electric or semi-electric stackers.

Maintaining your Pallet Stacking Machine

Motors and hydraulics on any pallet stacker needs regular maintenance and oiling of appropriate parts to keep them running smoothly. Operators should be trained in the correct use and care of all this type of equipment to ensure the full use of the stackers when needed for the task they will be undertaking. Regular checks save downtime and a well oiled machine is sure to give trouble free operation and longer life to the company. Never overload the stacker or try to carry extra riders as this may cause the stackers to tip or make them unstable.