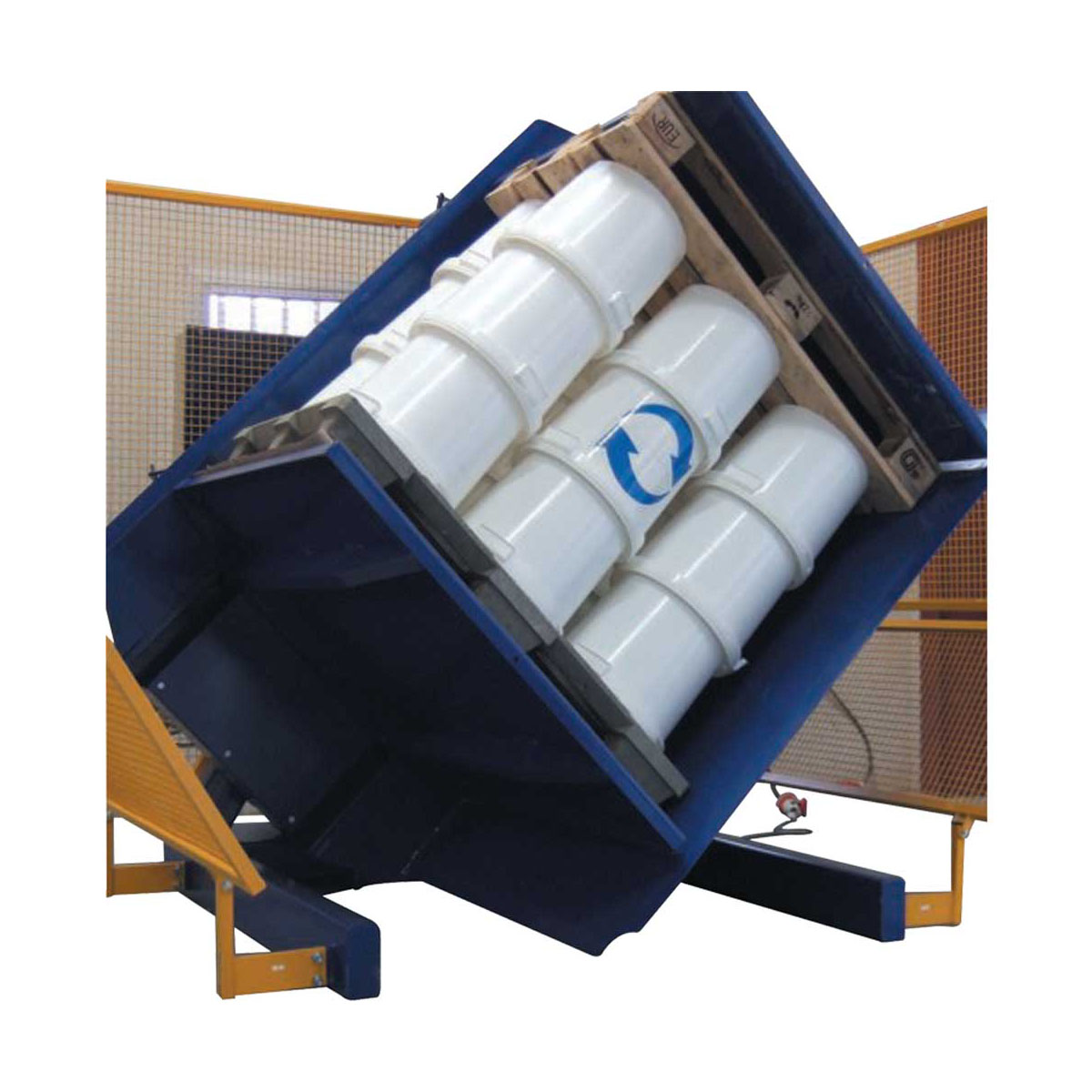

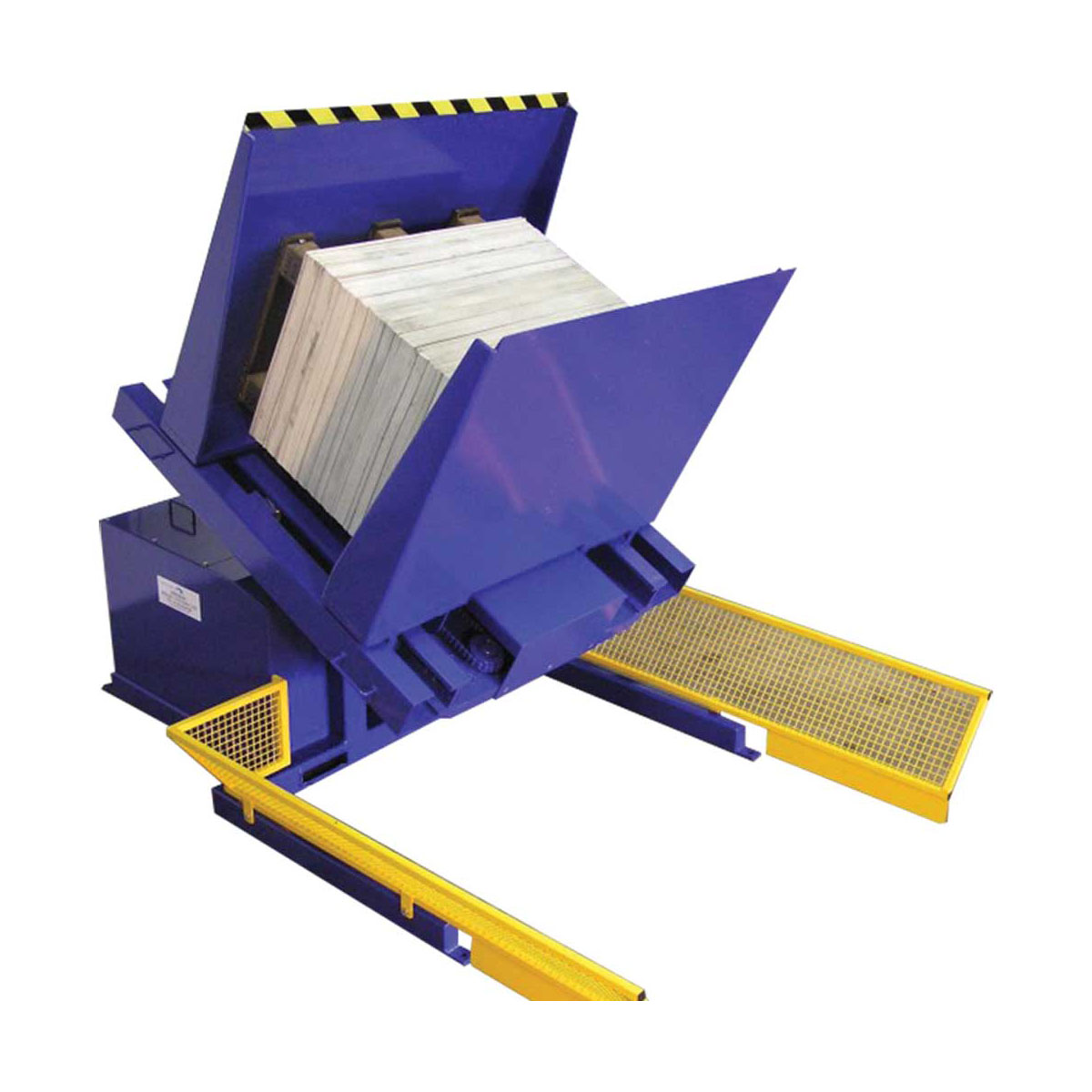

Types of Pallet Inverters and Changers

There are several types of pallet inverters and changers, each designed to meet specific needs and warehouse configurations. The most common types include:

Mobile Pallet Inverters/Changers These are portable, allowing easy movement within the warehouse, ideal for smaller operations or when flexibility is needed.

Floor-standing Pallet Inverters/Changers These are stationary, often used in larger warehouses, and can be integrated with conveyor systems for a seamless workflow.

In-line Pallet Inverters/Changers These are designed to integrate directly into your production line or conveyor system, offering a fully automated solution to pallet handling.

Key Features to Consider

When selecting a pallet inverter or changer, consider these essential features to ensure the best fit for your business:

a. Load Capacity

Choose a model with a suitable load capacity, taking into account the weight and dimensions of the goods you handle.

b. Pallet Compatibility

Ensure the chosen model can accommodate different pallet materials and sizes you use in your operation.

c. Safety Features

Look for safety features like load sensors, emergency stop buttons, and safety gates to ensure a secure working environment.

d. Ease of Operation

Opt for a user-friendly model with intuitive controls, making it easy for your team to operate with minimal training.

Proper Maintenance and Care

Regular maintenance is crucial to keep your pallet inverter or changer running smoothly and prolong its lifespan. Follow these best practices:

Regular Inspections

Inspect your machine routinely for wear and tear, damage, or any potential issues that could affect its performance.

Lubrication

Keep all moving parts well-lubricated to reduce friction and prevent premature wear.

Cleaning

Clean your machine regularly to remove dust, dirt, and debris that can affect its functionality.

Manufacturer's Guidelines

Always follow the manufacturer's maintenance recommendations and schedule to ensure optimal performance and longevity.

Astrolift is a leading supplier of warehouse and materials handling equipment, offering a wide range of innovative solutions, including pallet inverters and changers.