The Beak-Grip Drum lift attachment is easy to attach to a forklift for lifting single drums. It has a galvanized finish making it ideal for handling a wide range of steel or plastic drums. The parrot beak grip holds the drum tightly so that the operator does not have to leave the forklift.

The Drum Cradle is a manual cradle designed for 200 litre drums and this drum cradle can easily decant contents from the drums, taking all the hard work out of the tipping operation. Quick and easy work is made of the tipping process with this drum cradle.

The Drum Dolly comes in a range of carrying capacities and is either powder coated or galvanized which makes them strong and durable for all weather conditions. They have wheels or castors for fast and easy wheeling once the drum is positioned on the drum dolly.

Advantages of Drum Lifters

Drum Lifters make light work of lifting and carting drums and they have angled wheels making them suitable for larger drums and for picking up drums off pallets. Drums can be lifted and shifted in confined spaces and there is an option for an electric drum lifter as well. With the angled legs the drum lifters can be rolled or wheeled up to the corner of the pallet to pick up or put down the drum making it easy to lift drums on and off the pallets.

All this drum lifting, drum tipping and decanting handling equipment is time saving and stress free for moving, lifting, emptying, storing, weighing, rotating and pouring of liquids, powders and grains from drums in various types of industries such as chemical and petroleum industries, shipping yards, cosmetic companies, pharmaceuticals, grain handling companies and any industries where drums need to be shifted, filled or emptied in a safe and efficient manner. Where there is no such equipment available in the workplace the employees and workers are more prone to injuries from mishandling of heavy drums, therefore creating more downtime in the working environment.

Drum Lifter spade and strap type drum – the drum lifter spade can be lifted with the forklift and the driver does not need to leave his seat as this drum handler can lift a drum up to 200 litres without any hydraulic or electronic connections. The winding handle on the drum lifter spade attaches securely to the forks when picked up. The drum lifter with plastic strap has a stabilizing foot plate for securely lifting awkward drums, especially drums that do not have a lip or rim at the top.

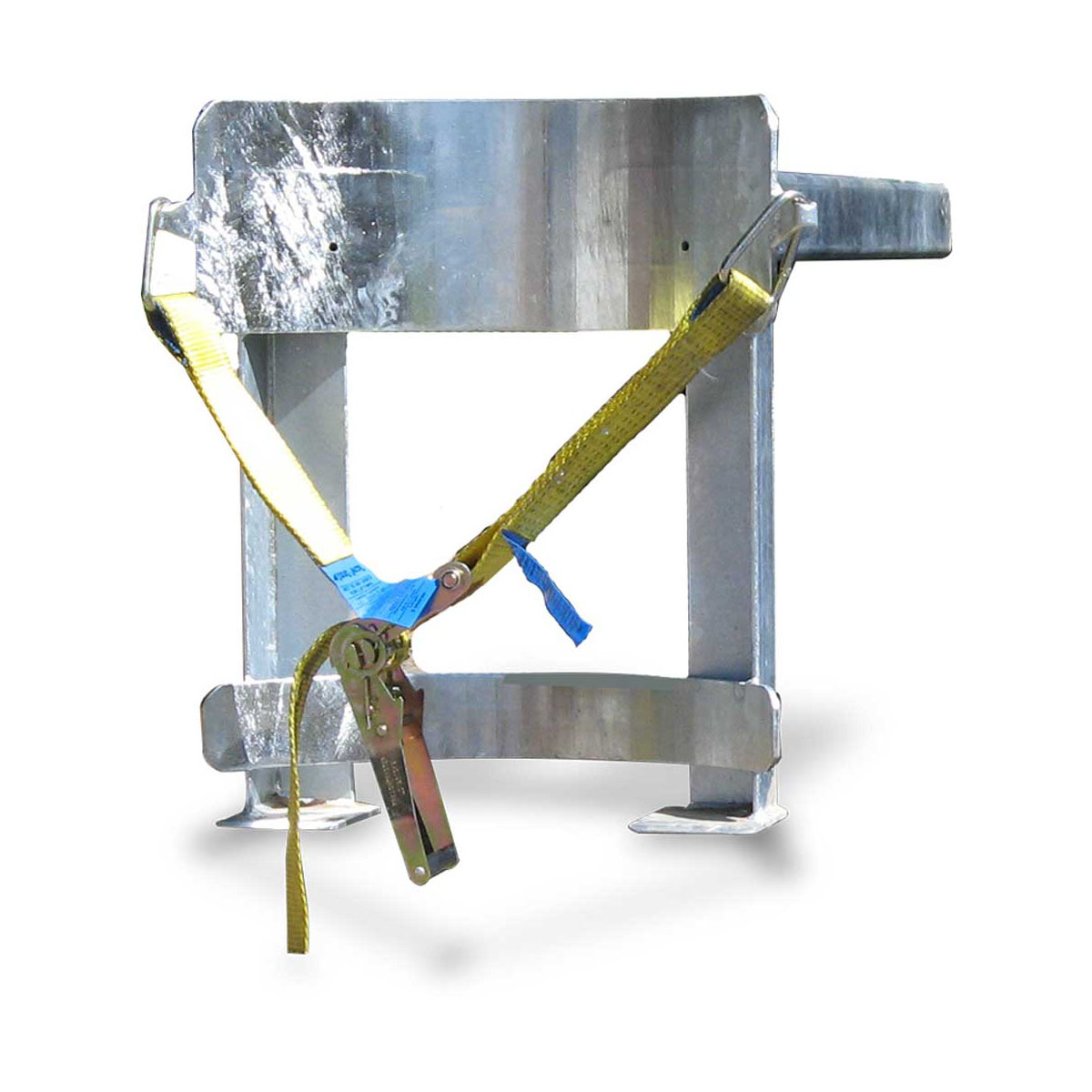

The Drum Rotator forklift attachment makes easy work of decanting drums with a forklift. Once the drum is secured with the ratchet strap it can be lifted and the crank wheel can rotate the drum sideways to decant. This drum rotator forklift attachment makes light work of decanting and tipping the contents of the drum in a safe and effortless manner.

Drum Handling Safety

Drums need to be handled by trained workers as mishandling of drums can lead to serious injury or can even be fatal depending on the contents of the drum. Full drums should not be rolled across the floor area or down a ramp as they can quickly gather speed and get away from the operator. Some drums are very difficult to grip and can be slippery to hold so need the straps or drum lifters to safely move them. One person should never try to lift or shift a full drum without the use of a drum lifter or drum tipper. Never overload a vehicle with drums whether full or empty as this can cause injury to unsuspecting people in the area.