Elevating personnel with a forklift is dangerous!

...if done incorrectly.

For safety reasons, forklifts should not elevate personnel with pallets, rail-less platforms or the bare forks. Forklift Man Cages are designed specifically for this situation.

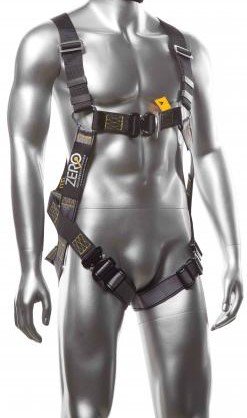

Forklifts, scissor lifts and other elevating work platforms such as cherry pickers can be used for accessing high work areas. Harnesses are not always mandatory when a forklift cage has full-height safety railing, however, it is still recommended to use a double lanyard system fixed to a certified anchor point.

Designed to the applicable requirements of NZS/ANSIJITSDF B56.1:2005 (Safety Standards for Low Lift and High Lift Trucks), our forklift cages are designed with two fall-restraint anchorage points for securing to the forklift, a mesh fence to prevent contact with the forklift's mast, safety railing on the remaining three sides, a latch swing-gate for access and kickboards to stop feet slipping over the platform's edge.

Safety guidelines for working elevated in a forklift cage

Having a forklift man cage but not knowing how to safely connect the cage to your forklift, or connect your harness to the fall restraints, can result in falling multiple metres and incurring injury.

According to Worksafe NZ, forklift platforms should: "be operated with the tilt lever on the forklift controls locked out or made inoperable; alternatively, a fall-restraint system comprising a full harness and short lanyard, allowing free movement only within the platform confines, shall be used."

See Worksafe's full Working At Height documentation here.

We recommend all personnel wear harnesses and lanyards in forklift man cages regardless of whether the forklift tilt controls are locked out.

- Once the forklift has picked up the cage, attach the restraining pins to the forks. These ensure that the man cage is secured and cannot slip forward on the forks and fall off.

- Ensure the platform is at ground-level before entering or exiting the attachment.

- Connect the end of your harness lanyard to the fall restraint loops at the bottom back of the cage. These restrain points stop a worker from falling out of the cage, and break their fall should they manage to do so.

- A trained forklift operator must be in a position to control the forklift at all times.

- Personnel's feet must remain on the platform at all times.

- Watch out for overhead obstructions when raising personnel.

- The mast must remain vertical and forks centred horizontally on the forklift - do not use the side-shift or tilt as this could unbalance the forklift.

- The forklift must remain in Neutral with the Parking Brake applied, keeping hands and feet away from any controls not in use.

- Smoothly lower and raise personnel only at their request.

- Only move elevated personnel horizontally for minor adjustments at their request.

Ensuring your forklift man cages and harness lanyards are correctly secured is paramount to the safety of your workers. Always make sure you double-check these before working at heights.