Why Do Warehouse Staff Ignore Safe Lifting Advice – and How to Fix it.

For younger warehouse workers, lifting with their legs feels "weird", and this is causing a pain in the back!

20% of all workplace injuries are related to lower back issues.

Lifting the right way is essential to employee safety, and to prevent Worker Compensation claims.

Even when you train employees to lift right – and we know that not everyone does – they frequently ignore or disregard the advice.

Why? - Because people are silly.

“It’s more comfortable lifting with your back than with your legs”

Workers in a busy operation will ignore the correct lifting techniques, even when they are systematically trained. Why? Because for some people it is more comfortable to lift the wrong way! It takes more energy. It feels unnatural to squat correctly to lift a heavy object.

According to the Archives of Physical Medicine and Rehabilitation, people said they would rather risk injury to their back than to breathe hard or strain to lift a box from a rack or shelf to the floor, to break down a pallet in the warehouse, or to handle any kind of difficult manual load.

Getting younger, physically active staff to act in a way that might not pay off until they are 40 or older is a tall order.

7 Tips & Tricks for better staff lifters

- Be vigilant in your training and schedule regularly. Don’t assume that just one training session will ensure training adoption.

- Ensure part of your managers’ training is to fully understand poor lifting techniques and how to correct them. Empower managers to reprimand workers who frequently lift with harmful techniques.

- Reduce the weight being lifted. If there is a repetitive process, can the loads be broken down into lighter parts?

- Invite older workers with back issues to speak with younger workers. Young can feel invincible, but nothing drives the point home like someone who has been through it all and suffered the consequences.

- Enforce mandatory work breaks. Make sure staff get proper breaks, especially when their duties typically involve manual lifting of goods. When staff are tired, proper technique can be forgotten. An alert and focused workforce is more productive AND safer.

- Utilize ergonomic equipment that helps workers lift better and easier. There are so many machines and so much equipment available to assist with movement of heavy loads.

- Utility material lifters are great in all warehouse and construction jobs.

- Spring loaded pallet lifters and electric pallet jacks are fantastic around an inventory warehouse. Maintaining product at a comfortable height, as well as taking the effort out of moving heavy goods around the floor.

- A unique product is the spring-loaded Ergobin, which is a self-levelling trolley for either goods or laundry. This bin automatically adjusts the height of the contents of the bin - so that staff are able to work at a comfortable level.

Communication is key.

Half the battle is the message. If the requirements of the job are not being understood clearly, this is a failure of management. Health and safety is no different. Ensure that H&S messages are supported from the top down and the expectation of staff is clear.

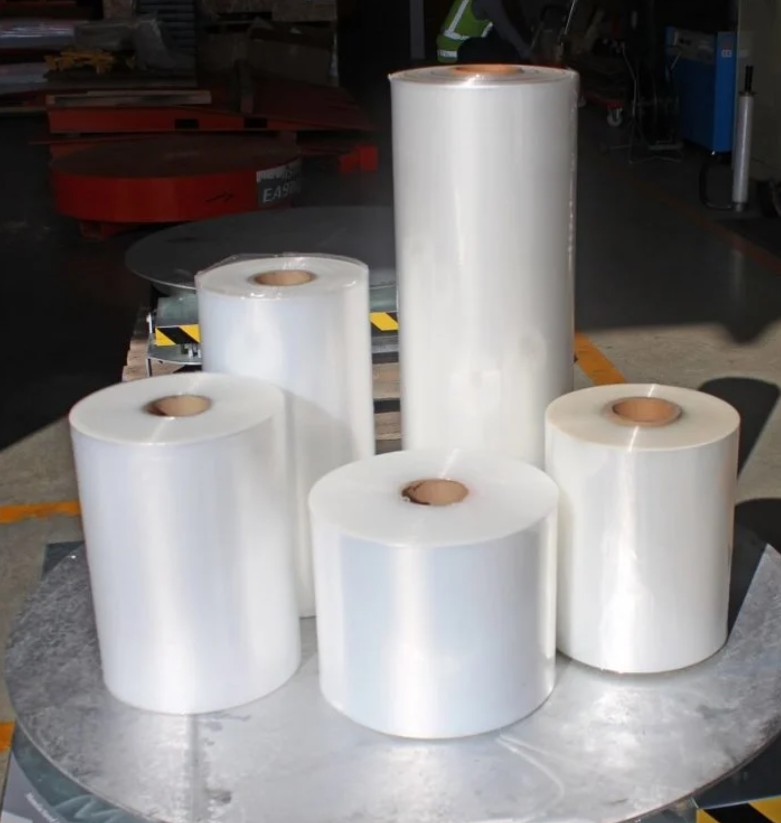

Machines and Equipment that can help people with bad backs:

Check out this range of products, specifically chosen for a various range of tasks. If you have any questions or would like to discuss any of these products - do not hesitate to contact us.