-

Products

Traffic Safety for Businesses

Access Equipment for Businesses

Barrier and Safety for Businesses

Materials Handling for Businesses

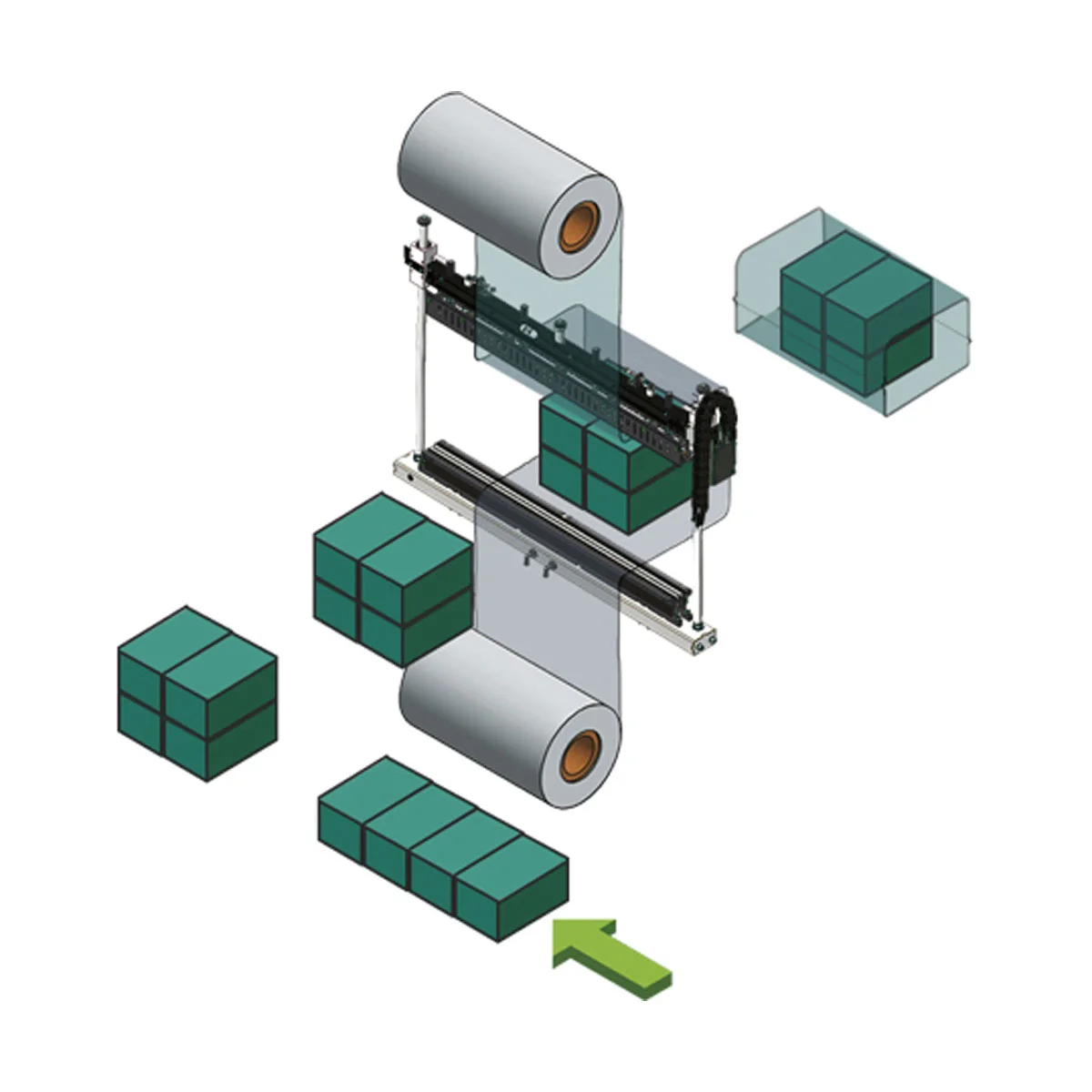

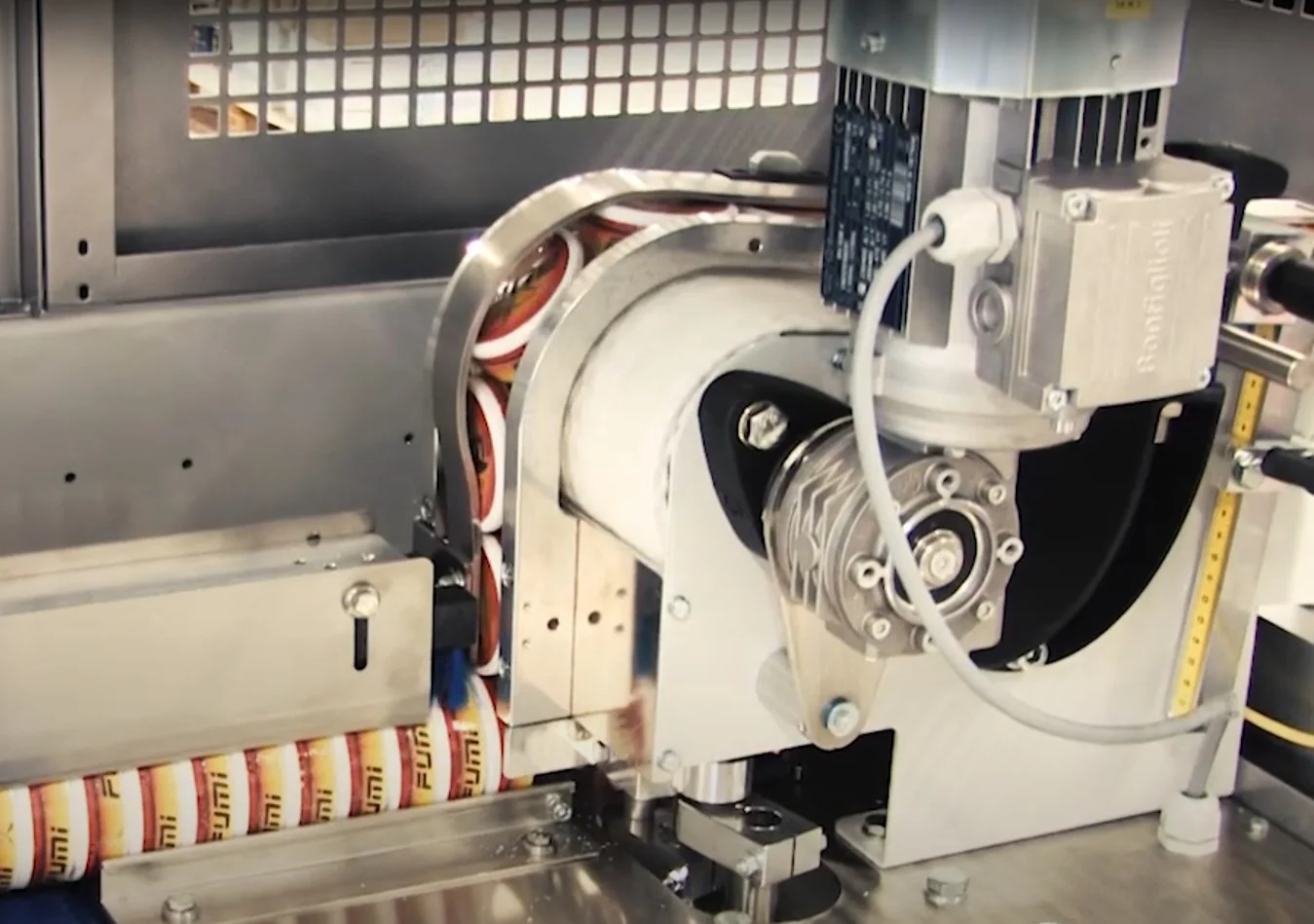

Packaging Equipment for Businesses

Request a Catalogue

Would you prefer a printed catalogue, or a PDF version?

-

For Industries

Construction for Businesses

Food Manufacturing for Businesses

Freight, Logistics & Distribution for Businesses

Laundries for Businesses

Manufacturing for Businesses

Retails & Supermarkets for Businesses

Request a Catalogue

Would you prefer a printed catalogue, or a PDF version?

-

Learn

Our Story

Proudly Supporting Safer Workplaces Across New Zealand

Find out more

- Traffic Safety

- Access Equipment

- Barrier and Safety

- Materials Handling

- Packaging Equipment

- For Industries

- Media Room

- About Us