Contrary to what most people think, typically hand-wrapping is neither a cheaper nor more efficient way to wrap pallets. Hand-wrapping pallets have some easily missed costs.

Pallet wrapping is the most common form of load containment around, used for securing product to pallets for distribution, storage, and protection from the elements. It has come a long way since its first introduction at the Packaging Machinery Manufacturers Trade Show in 1973!

There is a vast range of Pallet Wrappers available today, and given the range of configurations and features on offer, it's useful to have a brief guide to help you choose which is going to be the most helpful for your business.

Man vs Machine - The Hidden Costs

Product damage, labour, and material costs have the most significant impact when it comes to pallet wrapping. Most people typically look at the machine price tag when considering a new machine. When in fact - the price has the least impact. Although a pallet wrapper can reduce the extra expenditure from those three main cost driver might cost more upfront, it can pay itself off in a relatively short period through the savings it provides.

- Damaged Goods: Humans are fallible. We're not precision machines. So the strength and quality of hand-wrapped pallets will vary with every wrap. This inconsistency and lack of tension strength can create unsecured loads and cause in-transit damage to goods. Pallet wrappers stretch the wrap as it's applied to the load, making the material more durable, more puncture-resistant and more tear-resistant. It increases its ability to hold loads securely - decreasing the risks of transport damages and the cost of returns.

- Labour Costs: Hand-wrapping requires an operator's full attention and energy, and is more labour intensive than a machine. Utilising a pallet wrapper frees up your workers to spend their valuable time on more important tasks while the pallet is wrapping.

- Health and Safety Costs: Hand-wrapping pallets is a physically demanding job. It puts a considerable amount of strain on your workers, risking injury. Pallet wrappers reduce these potential risks along with eliminating tripping hazards associated with hand-wrapping.

- Material Costs: With a pallet wrapper, you can get an additional 30 - 400% wrap beyond their original film length. When compared to hand-wrapping, that's a significant potential saving in material cost.

- Throughput: Hand wrapping pallets is quite time-consuming. By hand-wrapping, you're not working as fast as you could be. A stretch wrap machine is typically much faster and more efficient.

- Customer Perception: Hand-wrapped pallets can be very uneven, messy and ununiform; this can leave a poor impression on a customer which can cause loss of future business. Pallet wrappers provide a consistent wrap every single time, keeping your pallets looking professional, tidy and secure.

Pallet Wrapper Types

Do you need a semi-automatic or fully-automatic machine? Should you get a turntable machine, a rotating-arm wrapper or a robotic unit? Knowing which types of machines are suitable for what you are wrapping is paramount. In this sub-article we go in-depth into the use cases and arguments for the different types of pallet wrappers.

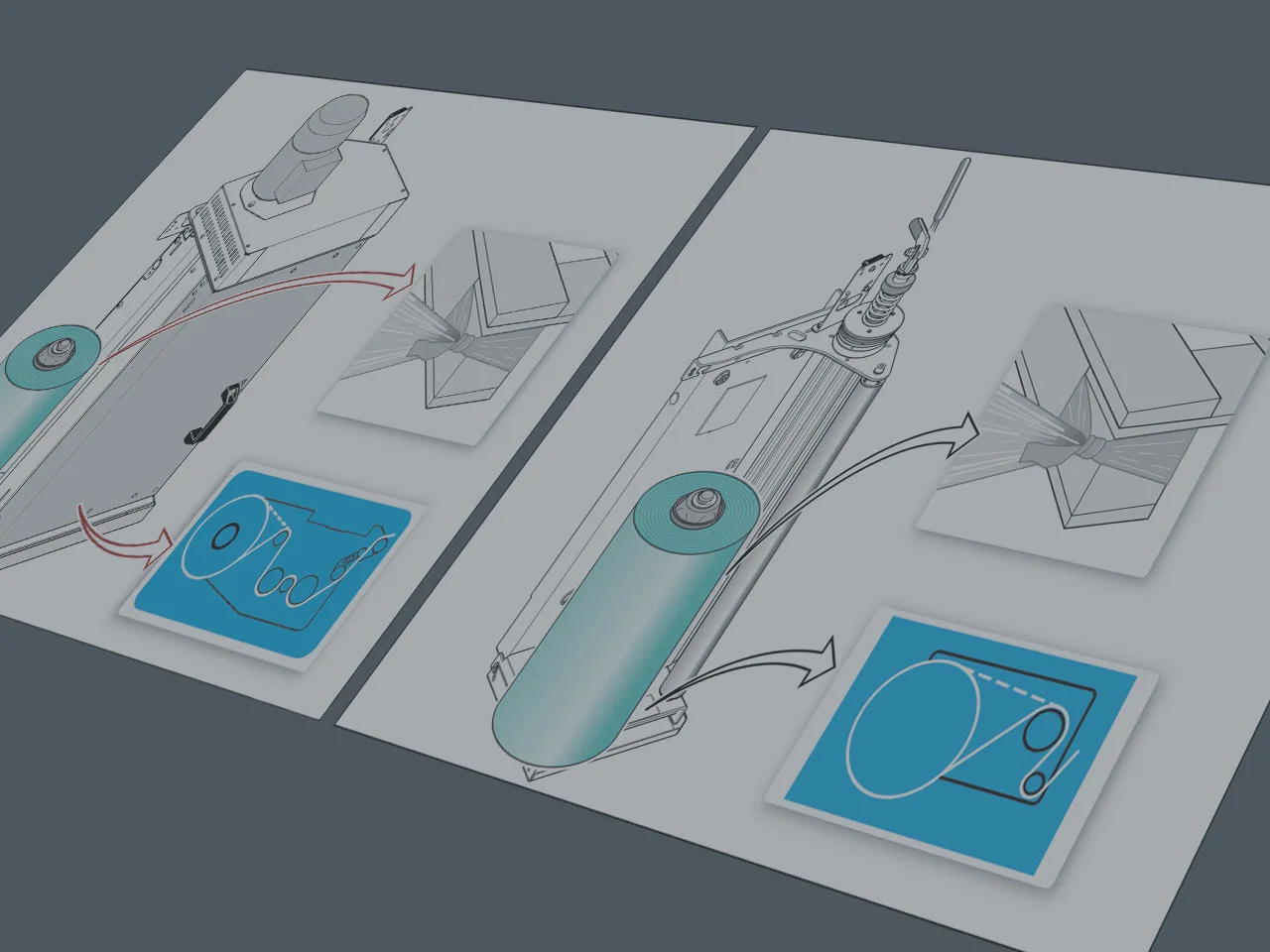

Wrap Heads

You've worked out which machine will suit what you're wrapping, now it's time to look at which type of film carriage you need. Although there are many small differences between wrap head models, this sub-article covers the the most important difference between them: Post-stretch vs Pre-stretch.

The Two Calculations of Pre-stretch

If you're needing a pre-stretch wrap head for your pallet wrapper, manufacturers throw an extra complexity at us - what percentage of stretch do you get? Manufacturers can calculate the amount of pre-stretch differently which makes it difficult for you to know for sure whether two machine actually provide the same amount of stretch. In this sub-article we illustrate how the two different methods are calculated so you don't get caught out.

Machine Configuration

You've got your machine sorted, and the wrap head. There are still a range of additional configurations available which we look at in more detail here.

Efficient and Cost Effective

Take a hands-off approach to your pallets, and make the most of the main benefits pallet wrappers provide over hand-wrapping methods.

- Speed: Increased wrapping speed compared with hand wrapping, for lower labour and material costs.

- Safety: Have better safety at work – less bending, fatigue, and reduced risk of trips and falls.

- Appearance: Make professional-looking pallets with secure and consistent wrap.

- Transportation: Secure and consistent wrap for reduced risk of damage during transit, and better protection from theft.

- Savings: The right machine, with the right configuration, can save you a lot of money on your consumable costs.

Next Article: