Large quantities of products are moved by pallets every day, and throughout their travels they sometimes need to have their supporting pallet changed.

This situation typically involves:

- Replacing a damaged pallet

- Swapping out a damaged box from the bottom of a loaded pallet

- Swapping to a different sized pallet

- Swapping from a rented pallet to an owned pallet

- Swapping from wooden pallet to plastic pallets

What is the advantage of a pallet changer?

To do a pallet swap manually, the load would need to be un-wrapped, manually un-stacked and re-stacked onto a different pallet.

Here is where Pallet Changers, or Inverters, save you time and effort. Instead of needing to un-stack a load, the pallet changer simply tilts or fully inverts the entire pallet and load. This removes the weight from the pallet and allows it to be swapped out.

Generally, pallet inverters are more applicable for production processes that heavily rely on changing pallets. When you have a high level of palletized goods and inputs coming into and out of your company, the time spent to manually de-stack and swap pallets can incur significant costs.

You can calculate the costs by making assumptions on time to swap pallets, how many pallets are swapped in a day, and the length of time and cost of labour to do this. There may also be an associated cost due to interruption to your other production processes.

What options are available?

Non-tipping Pallet Changer

This pallet changers grips the load from its sides, and lifts it vertically just enough that the pallet can be swapped out at ground-level.

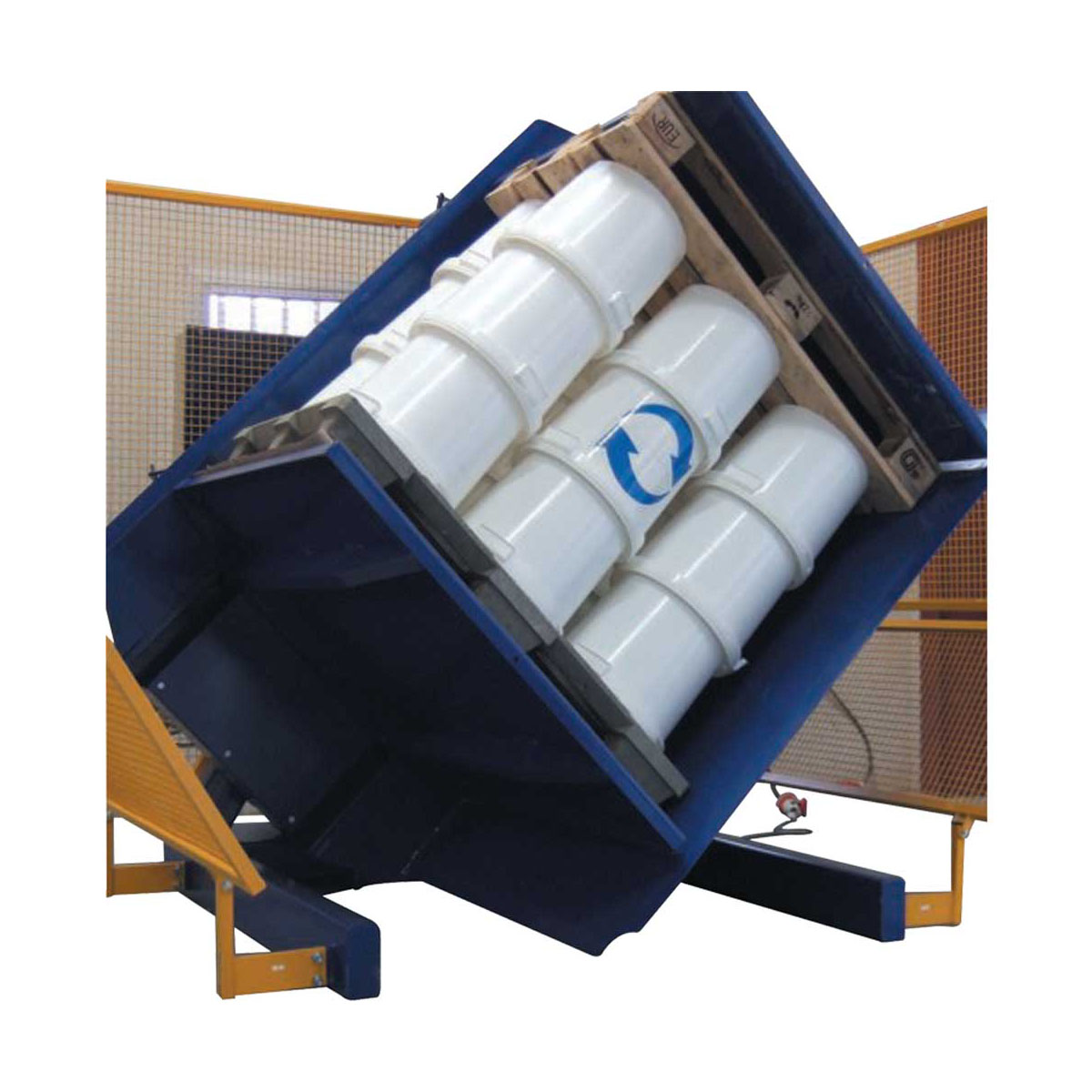

Tipping Pallet Changers

These pallet changers tip the entire load backwards, removing the weight from the pallet, before lowering the pallet back down for swapping at ground level.

Pallet Inverter

Pallet inverters will rotate the pallet through 180 degrees in order to change the pallet.

Once the load is securely in place, a new pallet is placed upside down on top of the load. The Inverter then grips the load top and bottom, then rotates it 180 degrees so the weight is on the new pallet, and the old pallet can now be removed from on top.

Less Time, More Safety

Pallet changers are not only an efficient way to replace a pallet from under a load, but they are also a key piece of machinery for protecting our employees from injuries caused by repetitive loading and unloading of pallets.